Quality control is essential in pillow block bearing manufacturing to ensure the products meet performance, safety, and durability standards. Leading manufacturers implement stringent checks starting from the selection of raw materials, particularly high-grade cast iron or stainless steel for housings and precision-machined bearing inserts. Throughout the production process, dimensional accuracy is maintained using CNC machinery and precision gauges. Bearings undergo thorough inspection for load tolerance, misalignment accommodation, and rotational smoothness. In-house testing, such as vibration analysis, noise level monitoring, and lubrication retention, ensures operational reliability. Many manufacturers also follow international standards like ISO 9001 and incorporate statistical process control (SPC) to monitor consistency and reduce defects, delivering bearings that perform reliably in diverse industrial environments.

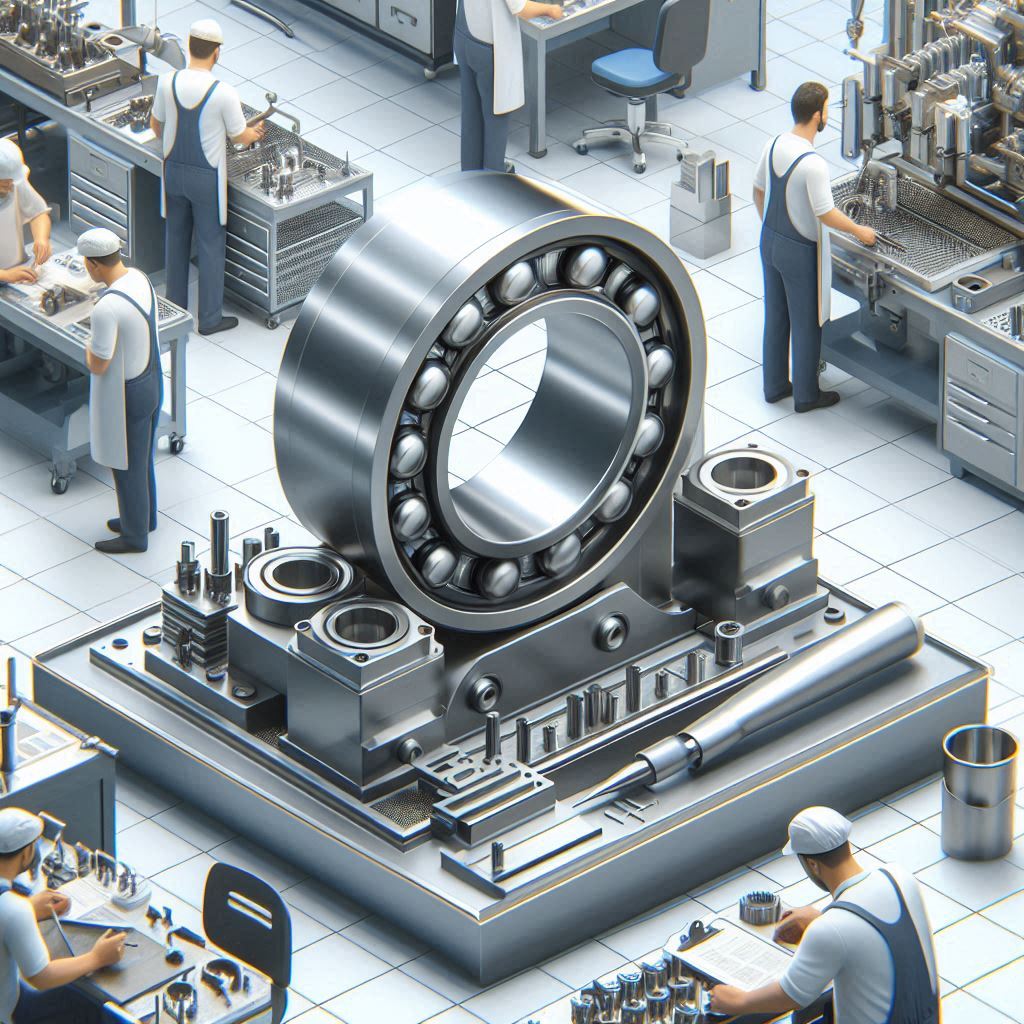

Understanding manufacturing process of pillow block bearing

The pillow block bearing manufacture involves a series of precise and controlled steps to ensure durability and performance. It begins with casting or forging the housing, typically from cast iron, ductile iron, or stainless steel, followed by CNC machining to achieve exact dimensions and alignment tolerances. The bearing insert, usually a deep-groove ball bearing, is manufactured separately using high-grade steel that undergoes heat treatment for enhanced strength and wear resistance. After assembly, the bearing is pressed into the housing and lubricated to reduce friction. Each unit is then tested for load capacity, smooth rotation, and noise levels. The process concludes with protective coatings or seals applied for corrosion resistance, making pillow block bearings reliable for demanding applications in industrial and agricultural machinery.

Different Application and uses of pillow block bearing

Pillow block bearings are widely used across a range of industries due to their ability to support rotating shafts and reduce friction in mechanical systems. In manufacturing and industrial plants, they are essential for conveyors, fans, and assembly line equipment, providing stable shaft support in high-load and high-speed environments. In the agricultural sector, pillow block bearings are used in machinery such as harvesters, tillers, and irrigation systems, where durability under harsh outdoor conditions is crucial. They are also commonly found in HVAC systems, packaging machinery, and material handling equipment. With their easy installation, alignment flexibility, and ability to handle moderate misalignments, pillow block bearings are a versatile solution for both light and heavy-duty mechanical applications.