In industries where lifting and securing heavy loads is a daily necessity, investing in heavy duty straps for lifting is not just important — it’s essential. From construction and warehousing to transportation and logistics, these robust tools provide the strength, safety, and reliability needed to get the job done efficiently and securely.

If you’re looking to enhance your lifting operations with quality equipment, understanding the value and application of heavy duty lifting straps can make all the difference.

What Are Heavy Duty Straps for Lifting?

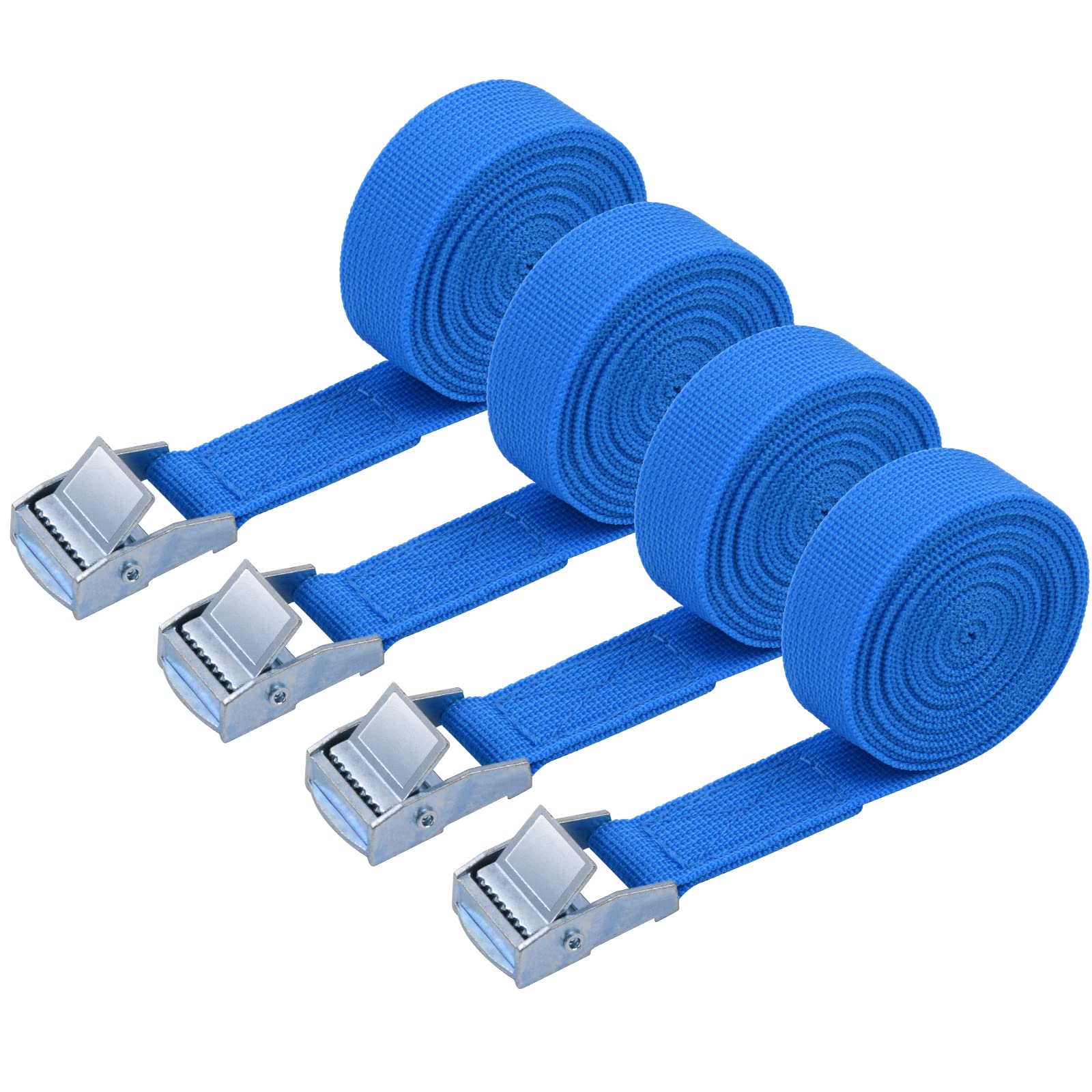

Heavy duty lifting straps, also known as lifting slings or cargo straps, are specially designed tools used to safely lift, move, and secure heavy items. Made from high-tensile materials like polyester, nylon, or webbing blends, these straps are engineered to endure extreme weight loads and rugged conditions.

They are often used with cranes, forklifts, hoists, or by manual lifting teams across a variety of industries, including:

- Construction

- Warehousing

- Shipping and logistics

- Manufacturing

- Automotive

- Agriculture

Benefits of Using Heavy Duty Lifting Straps

Superior Load Capacity

These straps are built to handle massive weight — often thousands of kilograms — without tearing or snapping. They provide a safe and stable lifting solution for machinery, equipment, and large cargo.

Enhanced Safety

Safety is a top priority during lifting operations. Heavy duty straps for lifting reduce the risk of workplace accidents by ensuring better grip and support, minimizing load shifting and falling hazards.

Durability and Long Lifespan

Manufactured with high-quality materials, lifting straps resist wear and tear from friction, weather exposure, oil, and chemicals. This durability translates into long-term cost savings.

Versatile Applications

These straps come in various lengths, widths, and configurations (flat, round, endless loops, etc.), making them suitable for lifting irregular shapes, fragile materials, or even delicate surfaces.

Compliance with Safety Standards

Reputable manufacturers ensure their straps meet international safety standards (such as EN, ASME, or ISO certifications), giving users peace of mind in critical operations.

Key Features to Look for in Heavy Duty Lifting Straps

When selecting the right container lifting lugs, keep the following features in mind:

1. Load Capacity / Working Load Limit (WLL)

Always choose a strap rated for your specific weight requirements. Exceeding the limit can lead to failures and safety risks.

2. Material Quality

Opt for materials like high-grade polyester or nylon for better strength, stretch resistance, and longevity.

3. End Fittings

Straps can come with hooks, D-rings, or loops — select based on the lifting mechanism you’ll use.

4. Weather and Abrasion Resistance

For outdoor or industrial use, make sure the strap resists UV rays, water, oil, and abrasive surfaces.

5. Certifications

Ensure the straps are tested and certified by industry safety standards to guarantee reliability.

Best Use Cases for Heavy Duty Lifting Straps

- Construction Sites: Lifting steel beams, concrete blocks, and construction machinery.

- Warehouses: Moving heavy pallets, crates, and storage units.

- Vehicle Recovery: Towing or lifting broken-down vehicles and machinery.

- Manufacturing Plants: Handling industrial equipment or raw materials.

- Shipping Yards: Loading and securing cargo containers or oversized packages.

Where to Buy Heavy Duty Straps for Lifting

You can purchase heavy duty lifting straps from:

- Industrial supply stores

- Online safety equipment retailers

- Material handling equipment specialists

- Custom manufacturers for tailored solutions

When buying online, always check product specifications, load ratings, and customer reviews to ensure you’re choosing reliable, high-quality products.

Final Thoughts

Whether you run a construction company, manage warehouse logistics, or handle machinery, using the right heavy duty straps for lifting is crucial for efficiency and safety. With their impressive load-bearing capabilities, durability, and safety compliance, these straps are a vital tool in any heavy-lifting environment.