In the age of electrification, automation, and sustainability, the auto parts manufacturing industry is at the heart of one of the most dynamic transformations in modern history. From electrified drivetrains to intelligent materials and additive manufacturing, this sector is not only keeping pace with evolving mobility trends but is also shaping the road ahead.

As a leading name in advanced composite solutions, Rockman Advanced Composites plays a pivotal role in steering innovation in this ever-evolving landscape. This article delves deep into how forward-thinking approaches, smart technologies, and sustainable practices are revolutionizing the auto parts manufacturing industry—and what it means for a smarter tomorrow.

1. The Changing Landscape of Auto Parts Manufacturing

Traditionally, the auto parts manufacturing industry has been characterized by standardized processes, high-volume production, and incremental innovation. However, recent years have witnessed a seismic shift.

Key Drivers of Change:

- Electrification of Vehicles (EVs)

With the rise of EVs, demand for lighter, more efficient components has surged. - Autonomous Driving Technologies

Smart sensors, cameras, and radar systems require precision-engineered parts with complex integration capabilities. - Environmental Regulations

Stringent emission standards and sustainability norms are pushing manufacturers to adopt greener production methods and recyclable materials. - Consumer Expectations

End-users now demand connected, intelligent, and sustainable vehicles, putting pressure on manufacturers to innovate continuously.

2. The Role of Advanced Materials in Innovation

At the core of modern automotive innovation lies the development and adoption of advanced materials—a field where Rockman Advanced Composites excels. Composite materials are transforming traditional notions of strength, durability, and weight.

Benefits of Advanced Composites:

- Weight Reduction

Carbon fiber and glass fiber composites reduce vehicle weight without compromising safety or performance, crucial for EV efficiency. - Corrosion Resistance

Ideal for components exposed to harsh conditions, such as underbody parts and battery enclosures. - Design Flexibility

Composites allow for complex geometries and seamless integration of multiple functions into a single component.

The integration of these materials helps the auto parts manufacturing industry move towards lighter, safer, and more energy-efficient vehicles.

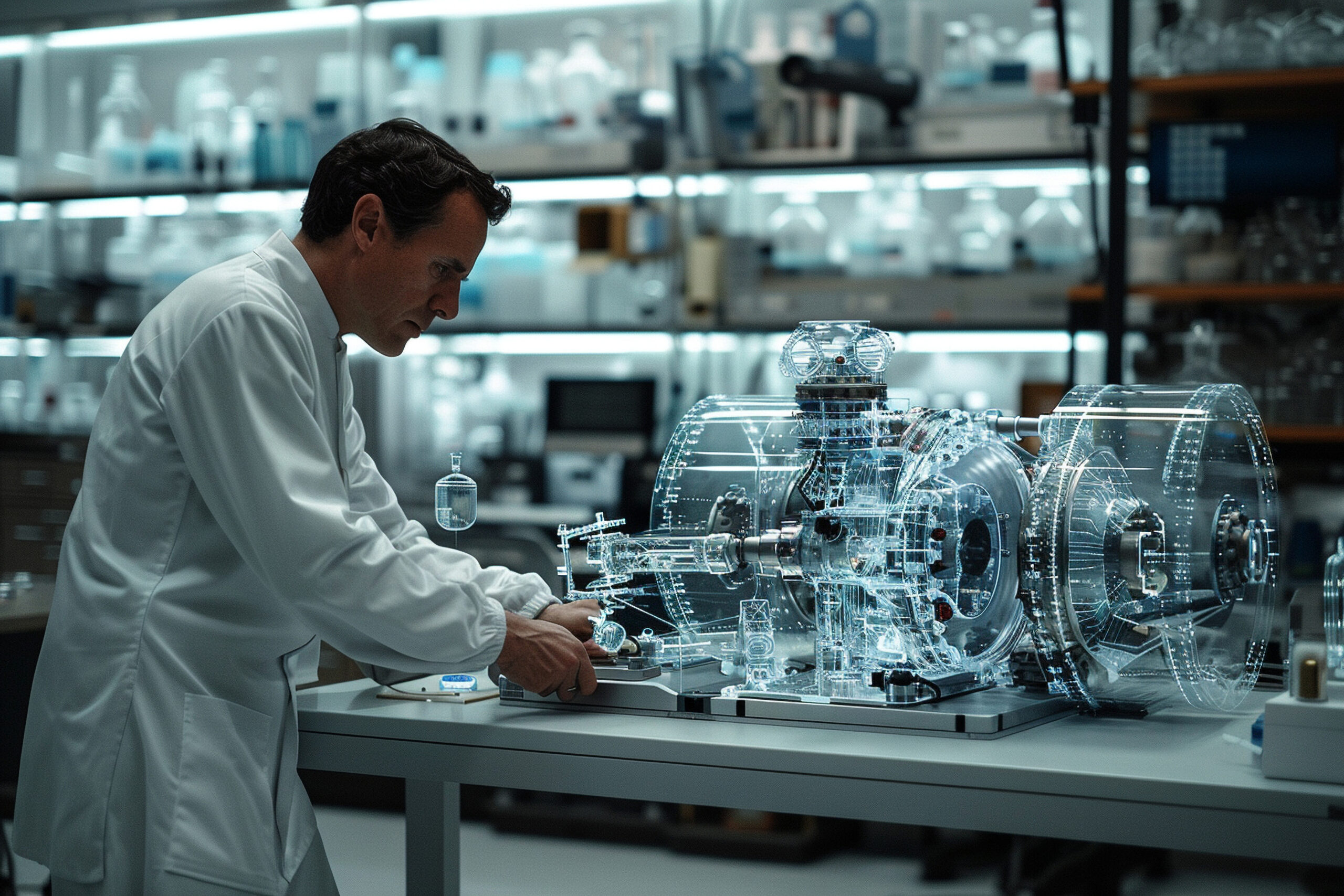

3. Smart Manufacturing: Industry 4.0 in Auto Parts

The fourth industrial revolution—Industry 4.0—has found fertile ground in the auto parts manufacturing industry. The integration of cyber-physical systems, the Internet of Things (IoT), and artificial intelligence (AI) is creating smart factories that are agile, responsive, and data-driven.

Key Innovations:

- Predictive Maintenance

Sensors monitor machinery in real-time, reducing downtime and improving efficiency. - Digital Twins

Virtual replicas of manufacturing processes allow simulations and adjustments before real-world implementation. - Automated Quality Control

Vision systems and AI detect defects more accurately and quickly than manual inspection.

Smart manufacturing enhances productivity, reduces waste, and supports the flexibility required to meet rapidly evolving customer demands.

4. The Rise of Additive Manufacturing (3D Printing)

Another groundbreaking trend reshaping the auto parts manufacturing industry is additive manufacturing, commonly known as 3D printing. This technology enables rapid prototyping, custom part creation, and on-demand production.

Advantages in Auto Parts:

- Faster Product Development

Design iterations can be tested within days instead of weeks or months. - Material Efficiency

Unlike subtractive methods, additive manufacturing uses only the material necessary, minimizing waste. - Customization

Easily accommodates low-volume, specialized components for luxury or performance vehicles.

With the ability to reduce time-to-market and support complex part geometries, 3D printing is bridging the gap between innovation and real-world application.

5. Sustainability: Green Manufacturing for a Clean Future

Sustainability is no longer optional—it’s a core mandate for the modern auto parts manufacturing industry. As governments and consumers demand cleaner production practices, companies are adopting environmentally friendly approaches.

Green Manufacturing Practices:

- Recycled and Bio-Based Materials

Using materials that are biodegradable or recyclable, including plant-based polymers and reclaimed carbon fiber. - Energy-Efficient Production

Leveraging renewable energy sources and optimizing machinery to reduce energy consumption. - Waste Reduction

Lean manufacturing and circular economy principles are minimizing waste across the supply chain.

Rockman Advanced Composites, for instance, continually innovates in using eco-conscious materials without sacrificing performance—paving the way for greener mobility.

6. Digital Transformation and Data-Driven Decisions

Digitalization is another key factor revolutionizing the auto parts manufacturing industry. From inventory management to predictive analytics, data is empowering manufacturers to make informed, agile decisions.

Digital Tools in Use:

- ERP and MES Systems

Streamline production and inventory tracking for real-time visibility. - AI and Machine Learning

Identify trends, optimize supply chains, and predict market demands. - Cloud Integration

Facilitates remote monitoring, collaboration, and scalability across facilities.

By combining data and automation, companies can respond more quickly to changes in demand, optimize resource utilization, and ensure traceability and compliance.

7. Supply Chain Resilience and Localization

The COVID-19 pandemic underscored the vulnerabilities in global supply chains. As a result, the auto parts manufacturing industry is prioritizing supply chain resilience and localization.

Emerging Trends:

- Nearshoring and Onshoring

Reducing dependence on overseas suppliers to avoid disruptions. - Supplier Diversification

Partnering with multiple vendors to mitigate risk. - Blockchain for Transparency

Ensures traceability, authenticity, and accountability in the parts supply chain.

Manufacturers who invest in resilient supply networks are better equipped to handle uncertainties and fulfill their commitments reliably.

8. Workforce Upskilling and Human-Machine Collaboration

While automation takes center stage, human expertise remains irreplaceable. The future of the auto parts manufacturing industry lies in human-machine collaboration—where advanced machines augment human skills.

Workforce Strategies:

- Continuous Training Programs

Equip employees with skills in robotics, AI, and digital systems. - Safety and Ergonomics

Automation reduces the need for repetitive or hazardous tasks, improving workplace safety. - Innovation Culture

Encouraging creative problem-solving and cross-functional collaboration.

At Rockman Advanced Composites, a deep investment in workforce development ensures that innovation is not just technological—but also cultural.

9. The Road Ahead: Connected, Autonomous, Shared, and Electric (CASE)

The auto parts manufacturing industry is not just reacting to change—it is enabling the CASE mobility revolution:

- Connected vehicles demand high-precision electronics and communication parts.

- Autonomous vehicles require advanced sensors, AI modules, and resilient hardware.

- Shared mobility solutions rely on durable and easy-to-maintain parts.

- Electric vehicles need high-performance battery enclosures, lightweight frames, and efficient thermal systems.

To remain competitive, manufacturers must anticipate these needs and design solutions that are flexible, scalable, and future-proof.

Conclusion: Innovating Today for a Smarter Tomorrow

As the mobility world pivots towards sustainability, intelligence, and efficiency, the auto parts manufacturing industry stands as a pillar of progress. Companies that embrace advanced materials, smart technologies, sustainable practices, and agile operations will not only survive—but thrive—in this new era.

At the forefront of this transformation is Rockman Advanced Composites, a pioneer in delivering high-performance, lightweight, and future-ready solutions for automotive OEMs worldwide.

By driving innovation at every level—from material science to digital integration—Rockman is helping build a smarter, cleaner, and more connected automotive future.