In today’s competitive manufacturing landscape, getting a product right before full-scale production is crucial. The ability to test and validate designs efficiently can save companies significant time and money. This is where prototype injection molding emerges as a game-changer. By providing manufacturers and designers with accurate, functional prototypes early in the product development cycle, this technique enhances testing and validation processes in ways traditional prototyping methods cannot match.

This article explores the benefits of prototype injection molding, how it improves product testing, and why it is a vital step for any company looking to reduce risks and optimize product performance before market launch.

Understanding Prototype Injection Molding and Its Role in Product Development

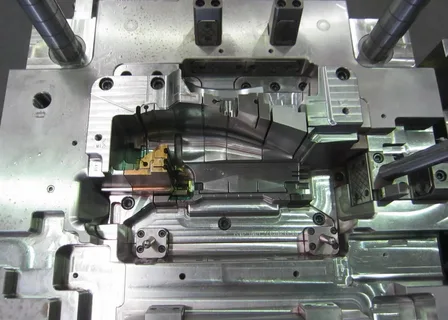

Prototype injection molding is a manufacturing process that creates plastic parts in small quantities, closely mimicking the final production parts made by injection molding. Unlike traditional prototyping techniques such as 3D printing or CNC machining, prototype injection molding uses molds similar to those in mass production, offering higher accuracy, better material properties, and surface finishes. This makes it an ideal choice for producing realistic prototypes that closely resemble the final product.

In the product development process, prototype injection molding serves as a bridge between initial design concepts and full-scale manufacturing. It allows engineers and designers to test parts in conditions closer to real-world usage. This helps identify potential design flaws, manufacturing issues, or material incompatibilities early on, significantly reducing costly revisions later in the production phase.

Enhancing Functional Testing with Realistic Prototypes

One of the biggest advantages of prototype injection molding is its ability to produce functional prototypes that replicate the mechanical and physical properties of the final product. These prototypes are made using the same materials or material families that will be used in mass production, providing a realistic testing platform. Functional testing includes stress tests, load bearing, thermal resistance, and durability assessments that are essential for ensuring product reliability.

By using prototype injection molding, manufacturers can conduct comprehensive performance evaluations under actual operating conditions. This level of testing accuracy is difficult to achieve with alternative prototyping methods that may lack proper material properties or surface finishes. As a result, companies can make informed decisions about design modifications and enhancements, leading to a stronger, more reliable product.

Accelerating Design Validation and Iteration Cycles

Prototype injection molding significantly accelerates the validation phase of product development. Because these prototypes are nearly identical to final production parts, they allow for quick validation of design intent, fit, and function. This means that teams can gather user feedback, perform assembly trials, and conduct regulatory compliance checks much earlier than with traditional prototyping methods.

Moreover, the relatively fast turnaround time and cost-effectiveness of prototype injection molding enable multiple iterations of prototypes within a short period. Design teams can rapidly test modifications, validate changes, and refine product features based on real data and customer insights. This iterative process helps minimize risks, avoid costly manufacturing delays, and ultimately speed up the time to market.

Reducing Costs and Risks Through Early Detection of Issues

One of the most compelling reasons to use prototype injection molding is its ability to uncover potential design or manufacturing defects early in the development cycle. By testing realistic prototypes, companies can identify issues such as warping, sink marks, material incompatibility, or assembly problems before committing to expensive production molds and tooling.

Early issue detection translates into significant cost savings. It prevents costly tooling modifications, scrap rates, and product recalls that can arise from undetected flaws. Additionally, this process mitigates the risk of launching a product that fails to meet performance expectations or regulatory standards, protecting the company’s reputation and customer satisfaction.

Supporting Better Communication and Collaboration Across Teams

Prototype injection molding also plays a crucial role in improving communication and collaboration among cross-functional teams. Because the prototypes closely replicate the final product, marketing, engineering, quality assurance, and manufacturing teams can use them as a common reference point. This shared understanding helps align expectations, reduce misinterpretations, and facilitate decision-making.

Furthermore, prototype injection molding allows stakeholders to physically interact with a tangible product, which is invaluable for product demonstrations, investor presentations, and user testing. This hands-on experience leads to more meaningful feedback and a clearer path toward final product approval. It fosters collaboration that drives innovation and ensures the product meets customer needs and market demands.

Conclusion

In summary, prototype injection molding offers unmatched advantages for product testing and validation. By providing high-fidelity, functional prototypes that mirror final production parts, it enables more accurate testing, faster validation cycles, early detection of manufacturing issues, and improved collaboration across teams. These benefits collectively reduce development risks, control costs, and accelerate time to market.

For manufacturers and designers aiming to deliver high-quality products efficiently, integrating prototype injection molding into the development process is no longer optional—it is essential. Embracing this technology ensures that products are not only innovative but also reliable, compliant, and ready to succeed in competitive markets.