In today’s fast-paced markets, product teams and manufacturers need reliable solutions to accelerate development while maintaining high-quality standards. That’s where quick turn injection molding becomes a game-changer. It offers a streamlined way to move from design to physical plastic parts in days, not weeks, enabling innovation without compromising efficiency or performance.

Whether you’re launching a new product, testing a design, or bridging the gap before high-volume production, quick turn injection molding delivers speed, precision, and value.

What Is Quick Turn Injection Molding?

Quick turn injection molding is a rapid manufacturing process that produces plastic components using CNC-machined aluminum molds. Unlike traditional steel tooling, which may take 6–10 weeks to fabricate, aluminum tooling can be produced in just a few days—significantly cutting lead time and cost.

It’s most effective for:

-

Low to mid-volume production (10 to 10,000+ units)

-

Design validation and engineering tests

-

Prototypes requiring production-grade plastic

-

Bridge production before full-scale launch

This process combines automation, high-speed machining, and simplified tooling strategies to deliver results quickly while retaining the quality of traditional molding techniques.

Key Advantages of Quick Turn Injection Molding

1. Ultra-Fast Lead Times

From CAD file to finished part in as little as 7 to 15 business days—quick turn injection molding drastically reduces development cycles. This is critical for startups, R&D departments, or time-sensitive production.

2. Cost-Effective Tooling

Aluminum molds are easier and faster to machine than hardened steel. This makes initial tooling more affordable, especially for low-volume or prototype projects, allowing companies to iterate freely without massive up-front investments.

3. Excellent Material Options

Despite its fast pace, this process supports a wide range of thermoplastics like ABS, polycarbonate, nylon, PEEK, and others. These materials meet various functional requirements, from chemical resistance to high-impact strength.

4. High Repeatability and Quality

Parts produced using quick turn injection molding maintain tight tolerances and excellent surface finishes. Advanced mold flow simulation and precision tooling help ensure dimensional accuracy across runs.

5. Scalable for Growth

Quick turn doesn’t mean one-time use. Many projects begin with a small run and scale up using the same mold, making it a great bridge between prototype and mass production.

Applications Across Industries

Medical and Healthcare

Hospitals and medical device manufacturers often rely on fast solutions to meet urgent market demands. Quick turn injection molding produces housings, surgical components, and functional prototypes for clinical testing—all with production-grade materials.

Automotive

Automotive R&D teams use this process for under-the-hood parts, dashboard prototypes, and small-batch customizations. Quick mold cycles allow faster regulatory testing and pre-production validations.

Consumer Electronics

Gadget developers benefit from rapid delivery of enclosures, bezels, and internal parts. Quick turn molding supports multiple revisions without slowing down the product release cycle.

Aerospace and Defense

Low-volume, high-precision plastic parts are essential in aerospace. This process allows teams to produce performance-grade parts for testing and short-run applications quickly.

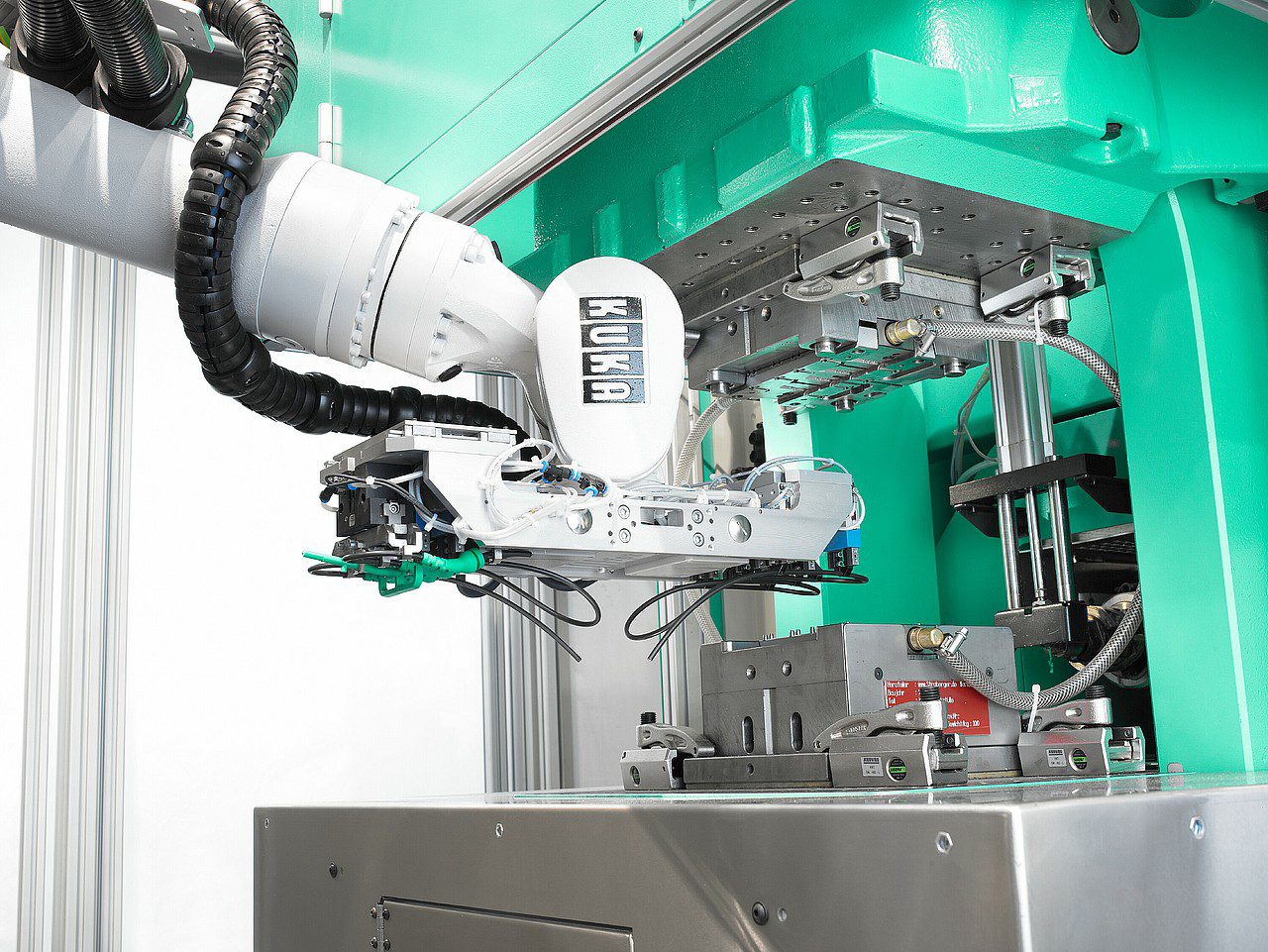

Industrial and Robotics

From cable guides to motor housings, industrial applications often require robust, function-first parts that can be iterated on quickly and delivered fast to avoid downtime.

The Process of Quick Turn Injection Molding

1. Design for Manufacturability (DFM)

You submit your 3D CAD model. Engineers run DFM analysis to evaluate draft angles, wall thickness, undercuts, and gate placement. This ensures the design is optimized for moldability and efficient cycle times.

2. Rapid Tooling Creation

Using CNC machining, the mold is cut from high-grade aluminum. This process is typically completed in 3 to 5 business days. Aluminum offers great thermal conductivity, reducing cycle time during part production.

3. Material Selection

Based on the application, you choose from a wide portfolio of thermoplastics. Mechanical properties, resistance characteristics, and appearance factors are considered during selection.

4. Injection and Quality Checks

The selected plastic is melted and injected into the aluminum mold at high pressure. Once cooled, the part is ejected and inspected. Dimensional checks, surface finishes, and tolerances are validated against project requirements.

5. Delivery and Iteration

Finished parts are delivered within 7–15 days. If changes are needed, mold modifications can be completed quickly, enabling design iterations in real time.

Why Choose Elitemold Tech for Quick Turn Injection Molding?

At Elitemold Tech, we bring years of experience, technical expertise, and high-speed CNC capabilities to deliver precision-molded parts—fast. Our team supports product development at every stage:

-

Free DFM consultation

-

Rapid tooling and mold delivery

-

Wide thermoplastic selection

-

ISO-certified quality assurance

-

Scalable production capacity

We serve startups, manufacturers, and product designers who require agility, reliability, and consistent quality in every project.

Whether you need 50 parts for testing or 5,000 parts for product launch, Elitemold Tech delivers with speed and confidence.

Common Use Cases

-

Bridge Production: Waiting on steel tooling? Use quick turn molds to meet demand without delay.

-

Beta Testing: Create multiple design iterations to validate ergonomics, functionality, or aesthetics.

-

Investor Demos: Produce working prototypes with actual materials for pitch decks and trade shows.

-

Early Market Launches: Test the market with real parts before committing to mass production.

-

Maintenance Spares: Fabricate low-volume replacements quickly for field operations.

Conclusion

In the race to deliver innovative products, manufacturers need fast, flexible solutions that don’t sacrifice quality. Quick turn injection molding fills that gap by offering production-grade plastic parts with rapid lead times and scalable output.

By working with a partner like Elitemold Tech, you gain access to advanced tools, material expertise, and responsive support—ensuring your parts are right the first time and on time.

For companies that value speed, precision, and service, this is the future of custom plastic manufacturing.