Introduction

Small automation projects often come with big challenges. Whether it’s a compact piece of machinery, a standalone process, or a cost-sensitive application, companies must balance reliability, performance, and affordability without overcomplicating the system. Traditional PLCs can be too large or expensive, while simple relays and timers lack the flexibility and intelligence needed for modern automation demands.

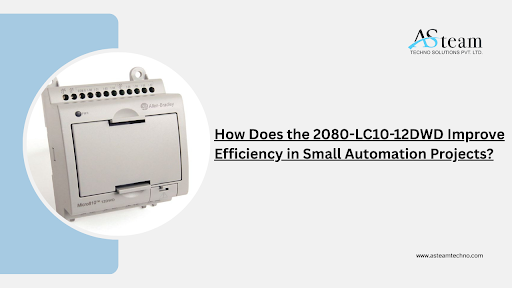

This is where Rockwell Automation’s 2080-LC10-12DWD Micro810 controller makes an impact. Designed specifically for small-scale automation, it offers essential control functions in a compact size, without the complexity or cost of larger controllers.

The purpose of this blog is to explore how this controller improves operational efficiency, reduces installation effort, and gives small automation projects a smarter and more scalable way to automate tasks.

Compact Design for Small-Scale Automation

Space often becomes a constraint in small machines and control cabinets. The 2080-LC10-12DWD’s compact footprint allows system designers to save valuable panel space while still gaining the functionality of a programmable controller.

Its size makes it ideal for tight enclosures or equipment where large PLCs are unnecessary. Beyond its dimensions, the Micro810 includes built-in smart relay functions, meaning your basic logic—like timers, counters, or scheduling—can be set up quickly without external components.

Another valuable benefit is the option for LCD/keypad programming, allowing technicians to configure simple operations without connecting a laptop. This flexibility speeds up troubleshooting, commissioning, and on-site adjustments, especially in remote locations where PC access is limited.

High-Capacity Output Handling and Reduced Hardware Costs

Many small automation tasks require switching pumps, small motors, lights, valves, or solenoids. The 2080-LC10-12DWD’s relay outputs are capable of driving loads directly, eliminating the need for interposing relays that add cost, wiring time, and maintenance.

Fewer external components mean fewer points of failure, translating into higher durability and long-term reliability. By directly controlling loads, maintenance intervals are reduced, and operators experience fewer unexpected shutdowns due to worn-out external relays. This upgrade alone significantly boosts performance without increasing budget.

Improved Programming and Scalability

Programming flexibility is a major advantage of this Micro810 controller. Using Connected Components Workbench (CCW), users can create applications with ladder logic, function block diagrams, or structured text, depending on their preference and complexity level.

Its fast scan time ensures the controller responds quickly to changing input conditions—critical in applications such as conveyor monitoring or precise timing control. The memory capacity and available analog-capable inputs make it suitable for varied small automation jobs that may still require sensor feedback or measured control.

Even though it’s designed for small systems, the scalability of its software means programs can later be migrated or expanded if the application grows—giving users room for future upgrades.

Versatility Across Different Small Automation Applications

The flexibility of the 2080-LC10-12DWD means it can support a wide range of applications. Some common uses include:

- Farming and solar-powered automation – irrigation pumps, greenhouse climate, and battery-powered controls.

- Small conveyors – packaging lines, sorting systems, light materials handling.

- Lighting and HVAC management – automated schedules, occupancy logic, and energy optimization.

- Water and chemical dosing systems – pump control, flow regulation, and safe dispensing processes.

- Gate and barrier automation – vehicle access, security doors, parking systems.

Because the controller integrates both digital and limited analog functionality, it serves these diverse roles without requiring costly add-ons or expansion units.

Cost Efficiency Over Larger PLCs

Budget is one of the biggest decision factors in small automation projects. The Micro810 stays cost-effective by reducing:

- Wiring and installation hours

- External relay components

- Cabinet size requirements

- Programming and commissioning time

For applications with fewer than 12 I/O points, using a large PLC platform becomes unnecessary and expensive. The 2080-LC10-12DWD offers the automation power required—without the overhead and investment typically associated with larger systems.

Conclusion

The 2080-LC10-12DWD Micro810 controller proves that small automation projects don’t need to settle for limited functionality or oversized control systems. With its compact design, built-in smart features, strong output capacity, and flexible programming environment, it delivers efficiency and reliability suited for a wide range of applications.

For organizations looking to modernize small machines or replace outdated relay-based controls, this controller provides a practical and affordable pathway into smarter automation.

Frequently Asked Questions (FAQs)

Q1: Is the 2080-LC10-12DWD suitable for beginners in automation?

Yes, it is beginner-friendly, especially with LCD/keypad programming and basic CCW software tools.

Q2: Can it handle analog inputs?

Yes, some input points support analog signals, allowing integration with basic sensors.

Q3: Do I always need a PC to program the controller?

No, simple tasks can be configured using the optional LCD/keypad interface.

Q4: What type of loads can the relay outputs control?

It can directly switch pumps, lighting, solenoids, and other small electrical loads.

Q5: Is this controller cost-effective for small projects?

Absolutely—its built-in features and reduced wiring make it ideal for low-budget automation tasks.

Reach Us

Asteam Techno Solutions Pvt. Ltd. is AVEVA (Formerly Wonderware) Registered System Integrator providing sale/service/support and executing the HMI/SCADA, Historian/MES Solutions to End-user & OEM/System Integrator community for their diverse needs.

Leading single-source supplier & solution provider for industrial automation hardware and software solutions needed.

Preferred wholesale supplier, stockiest & exporter of Programmable Logic Controller (PLC), Drive (VFD), HMI, Panel PC, SCADA, Profibus Connector, Cable, and many more automation products.

We serve OEM, Pharmaceuticals, Chemicals, Petrochemicals, oil & gas, Panel manufacturers along with our process equipment. Also, we deliver services to Food processing OEM, electrical industries & mechanical industries with our special purpose process components.