India’s manufacturing industry is expanding rapidly, especially in automotive, heavy engineering, fabrication, and infrastructure sectors. As production demands increase and quality standards become stricter, more factories are turning to welding automation to stay competitive. Choosing the best welding robot manufacturers for industrial use in India is an important decision that directly affects productivity, weld quality, and long-term operational stability.

Welding robots are no longer limited to large multinational plants. Today, both mid-sized and large-scale industries are investing in robotic welding systems to reduce errors, improve consistency, and increase output.

Why Industrial Welding Robots Are in High Demand

Manual welding depends heavily on operator skill and physical endurance. Even experienced welders may produce slight variations in weld quality over long shifts. In industries like automotive manufacturing, even small inconsistencies can lead to rejection, rework, and financial losses.

A robotic welding machine in India ensures:

- Consistent weld penetration and finish

- Higher production speed

- Reduced material wastage

- Improved worker safety

- Lower long-term labor dependency

Industrial robots maintain precise movement, arc length, and positioning throughout the welding cycle. This level of accuracy is essential for high-volume production environments.

What Defines the Best Welding Robot Manufacturers?

When selecting a robot welding machine company, manufacturers should evaluate more than just equipment pricing. The best welding robot manufacturers for industrial use in India offer complete solutions rather than just standalone machines.

Key factors to consider include:

1. Industry Experience

Manufacturers with strong experience in automotive and heavy fabrication industries understand real production challenges.

2. Customization Capability

Every factory has different production layouts. The best suppliers provide customized robotic welding cells based on payload, reach, and cycle time requirements.

3. Integration Expertise

Welding robots must integrate smoothly with positioners, fixtures, conveyors, and safety systems.

4. Service and Support Network

After-sales service is critical. Quick response time, spare parts availability, and preventive maintenance support reduce downtime significantly.

Welding Robot Manufacturing Hubs in India

Several regions in India have become strong centers for industrial automation. Coimbatore, in Tamil Nadu, is one of the growing hubs for automation technology.

Many factory owners actively search for:

- Welding robot suppliers in Coimbatore

- Robotic welding machine manufacturers in Coimbatore

- Reliable welding automation company in Coimbatore

The advantage of working with automation companies in Coimbatore is faster service support and better understanding of regional industrial requirements.

Importance of Local Service Centers

Industrial welding robots operate in demanding environments with heat, fumes, and continuous production pressure. Without proper maintenance, performance can decline over time.

The best welding robot manufacturers in India provide:

- On-site installation and commissioning

- Operator training

- Preventive maintenance programs

- Software upgrades

- Quick breakdown support

This level of service ensures that robotic systems continue operating at peak performance.

Role of Automation Partners in Industrial Growth

Automation is not just about installing a robotic arm. It requires proper planning, layout analysis, and process optimization. Manufacturers often work with experienced automation solution providers to assess production targets and recommend the right welding robot system.

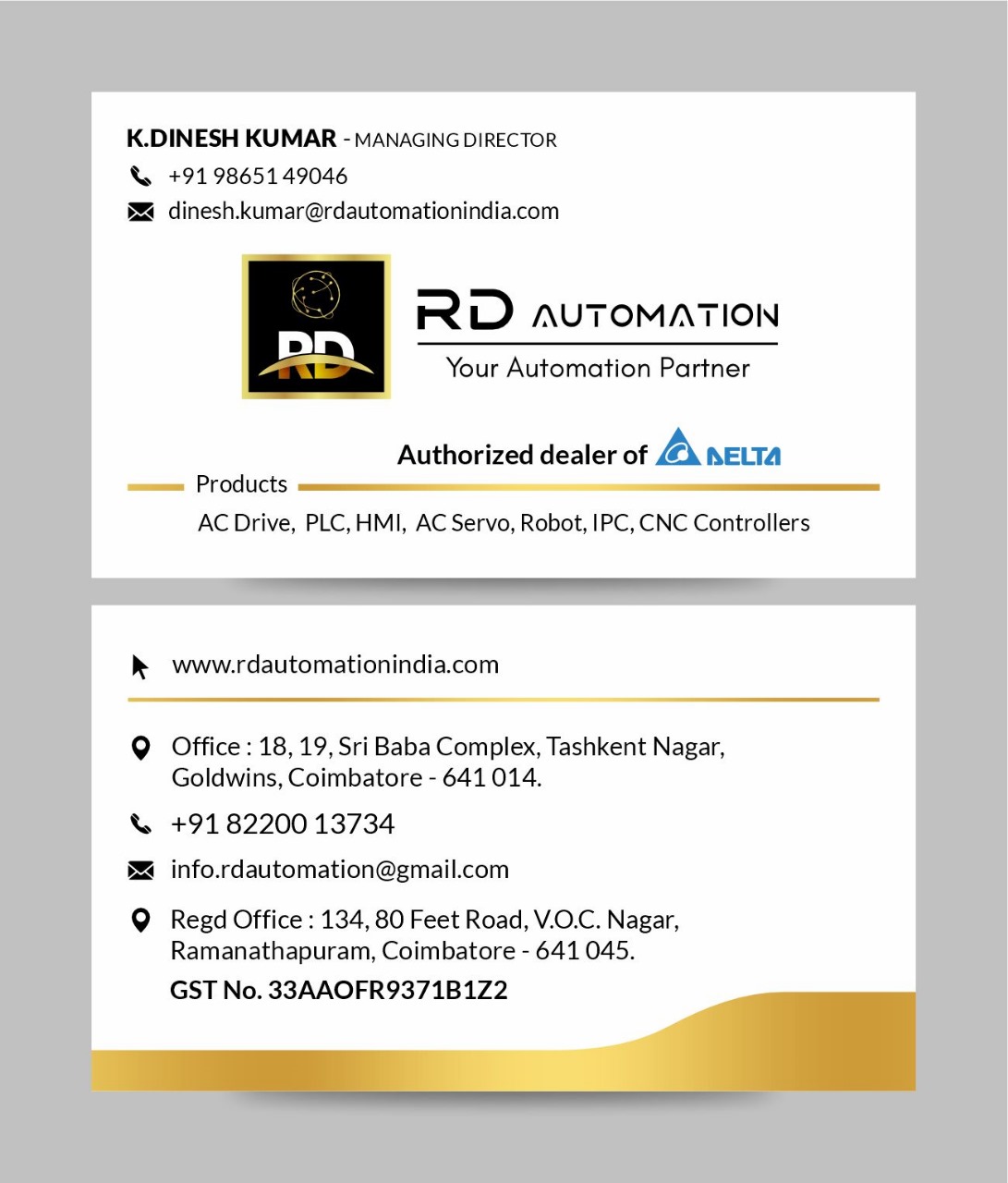

Companies like RD Automation support industrial clients by delivering practical welding automation solutions tailored to Indian manufacturing conditions. With experience in robotic welding integration, they help factories implement systems that balance performance, safety, and long-term cost efficiency.

For automotive manufacturers especially, selecting the right robot welding machine company ensures better production consistency and compliance with global quality standards.

Future of Industrial Welding Robots in India

The adoption of robotic welding machine in India is expected to grow significantly in the coming years. Industry 4.0, smart manufacturing, and increasing export demands are pushing factories toward advanced automation.

Manufacturers who invest in reliable welding robot systems today position themselves for long-term competitiveness. With consistent weld quality, higher throughput, and improved worker safety, welding robots are becoming essential rather than optional.

Final Thoughts

Choosing the best welding robot manufacturers for industrial use in India requires careful evaluation of technical capability, customization options, and service support. Whether operating in Coimbatore, Tamil Nadu, or other industrial regions, factory owners should focus on long-term value rather than just initial cost.

With the right automation partner and well-planned implementation, welding robots can transform industrial production by improving accuracy, reducing downtime, and supporting sustainable growth.