Mixing looks simple until it goes wrong. A sample that settles too quickly, reagents that do not interact evenly, or tubes that receive different levels of agitation can quietly undermine your results. This is where rotator lab equipment proves its value. It offers controlled, gentle motion that keeps samples uniformly mixed without introducing stress or damage.

Many labs begin with manual inversion or short vortex bursts. That approach works for quick tasks, but it becomes unreliable as protocols grow more complex. Rotators provide continuous motion that supports long incubation periods and delicate sample handling. Once you rely on them regularly, they become part of the background rhythm of your lab.

Understanding how this equipment improves sample processing helps you choose the right setup and apply it correctly across workflows.

Why Gentle Rotation Matters in the Lab

Not every sample benefits from aggressive mixing. Blood specimens, antibody binding reactions, and cell suspensions often require slow and consistent motion. Too much force can shear cells or disrupt molecular interactions. Too little motion allows settling and uneven exposure.

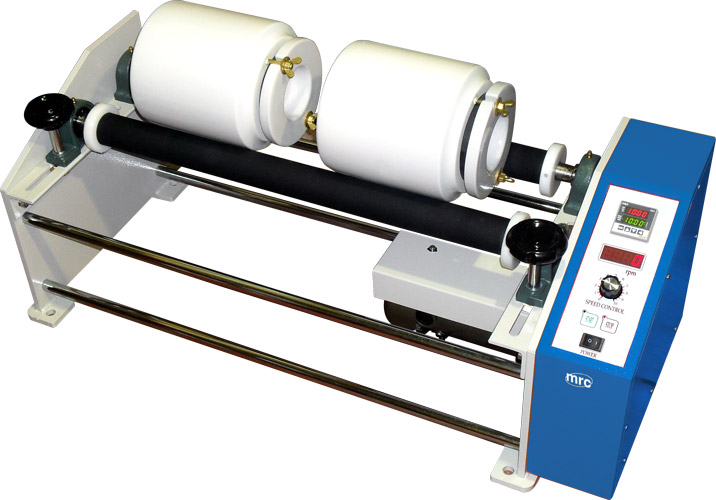

Rotators solve this problem by keeping samples in constant motion at controlled speeds. Tubes rotate end over end or at fixed angles, which keeps contents suspended while preserving sample integrity. This balance supports reliable reactions without the variability of manual handling.

This is one reason rotator lab equipment appears so often in clinical, molecular, and immunology labs.

Common Applications That Depend on Rotators

You often see rotators used during blood sample preparation, where gentle mixing preserves cell structure. They also support antibody incubation steps in immunoassays, where uniform exposure improves binding consistency.

In molecular workflows, rotators keep beads, resins, or particles evenly distributed during binding and washing steps. This improves yield and repeatability. In microbiology, slow rotation supports suspension cultures and reagent mixing without foaming.

Because these tasks often run for extended periods, automation becomes essential. Rotators allow you to walk away while maintaining consistent conditions.

How Rotators Improve Workflow Efficiency

Efficiency is not only about speed. It is about predictability. When mixing becomes standardized, downstream steps become easier to control. You spend less time troubleshooting and repeating steps.

Rotators also reduce physical strain. Instead of repeatedly inverting tubes or returning to vortex samples, you load them once and let the equipment handle the rest. Over time, this reduces fatigue and improves focus on analysis rather than preparation.

Labs looking for dependable solutions often consider trusted companies like NE LabSystems when selecting rotators that deliver consistent performance across daily workflows.

Choosing the Right Rotator for Your Needs

The right rotator depends on tube size, sample volume, and rotation style. Some workflows benefit from fixed-angle rotation. Others require adjustable angles or continuous end-over-end motion. Speed control also matters, especially for sensitive samples.

Ease of cleaning and stability during long runs should factor into your decision. A well-designed rotator maintains balance even when fully loaded, which protects both samples and equipment.

Reliable equipment from established suppliers like NE LabSystems often includes design features that support long-term use without excessive maintenance.

Final Note

Rotator lab equipment plays a quiet but essential role in sample preparation. By delivering gentle, consistent motion, it protects sample integrity and improves reproducibility across workflows. When mixing is controlled, results become easier to trust.

If your lab handles sensitive samples or extended incubation steps, understanding how rotators support processing helps you build smoother and more reliable protocols.