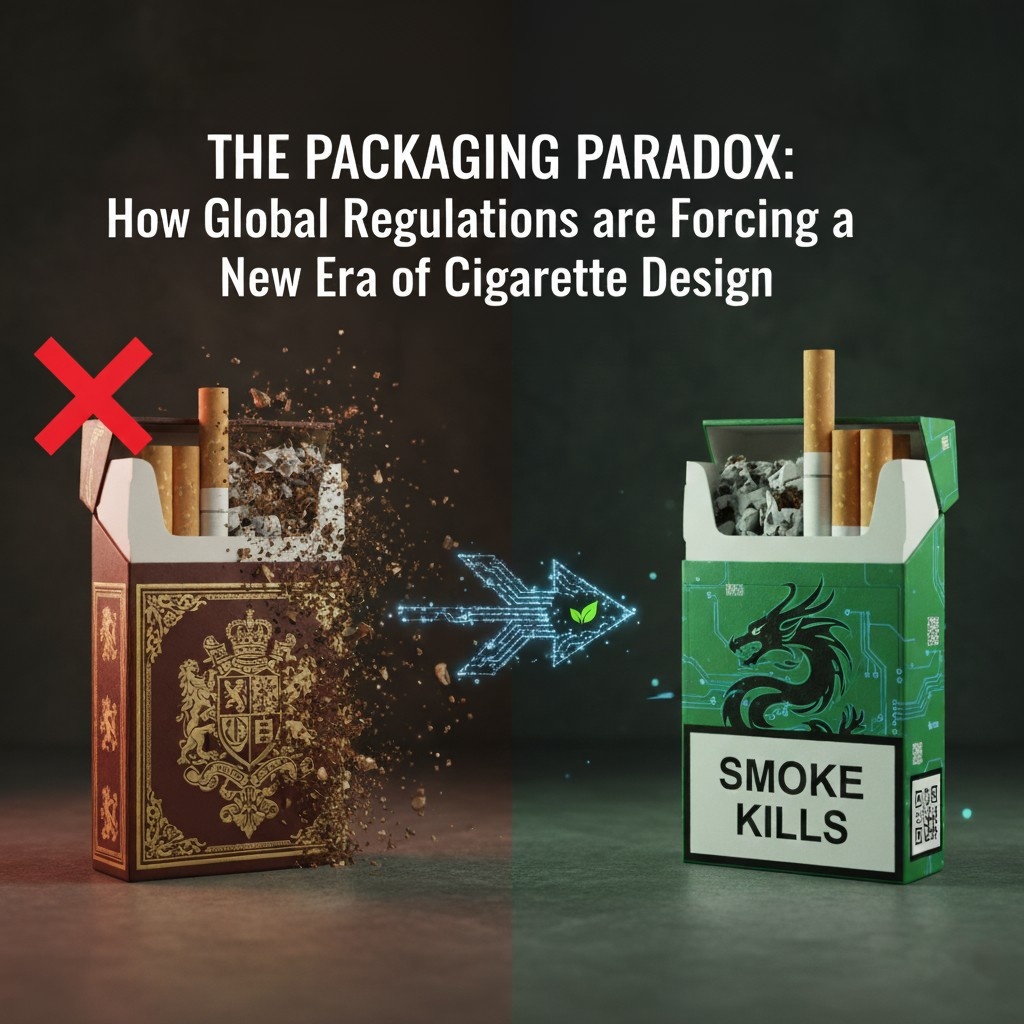

The role of a cigarette box has fundamentally changed. It is no longer a canvas for marketing; it is a fortress of compliance and a carrier of critical data. Driven by global public health mandates, the industry has shifted away from dazzling aesthetics toward an era defined by security, sustainability, and precise engineering.

As specialists in custom packaging, we understand that this transformation presents a complex challenge. The value of the modern tobacco package lies in its ability to meet the world’s strictest rules while protecting the product and fighting illicit trade.

Here is a look at the pressures, strategies, and essential innovations defining the future of cigarette packaging.

The Regulatory Squeeze: Design Restrictions

The most powerful force shaping the new packaging landscape is government policy aimed at reducing the visual appeal of tobacco products.

The Standardized Look

The adoption of Plain Packaging laws across the globe has severely limited design options. These rules enforce uniformity across several critical areas:

-

Aesthetic Ban: All decorative branding, logos, special finishes, and attractive colors are stripped away. Packs must be a specific, uniform, unappealing color (like matte olive-green).

-

The Size of the Warning: Branding real estate has been replaced by massive, graphic health warnings that now dominate the pack’s surface, often covering 65% to 90% of the display area.

-

Font and Text: Brand names are reduced to a small, standardized font, removing any ability to convey brand personality through typography.

Environmental Responsibility

The push for a smaller ecological footprint is now a non-negotiable requirement, driving changes in material science:

-

Sustainable Sourcing: There is a heavy reliance on FSC-certified paperboard and recycled materials for the main carton.

-

Biodegradable Barriers: Companies are actively replacing traditional plastic films and liners with compostable or biodegradable alternatives that preserve product freshness while minimizing environmental harm.

Innovation in the Invisible: The Core Function

With visual design eliminated, manufacturers must embed innovation within the packaging structure itself to ensure authenticity and supply chain integrity.

-

Anti-Counterfeiting Defense: Since the visual brand is gone, the packaging itself must prove authenticity. This involves covert holographic features, special security inks, and micro-printing that are invisible to the naked eye but easily verifiable by authorities.

-

Track-and-Trace Systems: Global regulations require the pack to be a data carrier. This means printing unique serialized codes and using advanced QR code/NFC technology on every pack, which allows governments to track the product from the factory to retail, fighting illicit trade.

-

Structural Excellence: The physical design, such as the snap-close hinge or the internal foil liner, becomes the only non-verbal differentiator left. Innovation focuses on making the pack more robust, protecting the cigarettes better, and improving the user’s experience of opening and closing the pack.

Frequently Asked Questions (FAQs)

Q: Why are governments prioritizing “plain” packaging over just large health warnings?

A: Research indicates that plain packaging policies are more effective because they eliminate both the visual appeal and the false perception of reduced harm often conveyed by different colors (e.g., light blue implying “lighter” or “milder” tobacco). Standardization ensures the health message is the sole focus.

Q: How does the industry differentiate its premium products without branding?

A: With visual branding severely limited, premium brands often rely on tactile differentiation. This can include using higher-quality, heavier cardboard, matte or unique soft-touch finishes, and precision-engineered opening mechanisms that convey a sense of luxury through touch and structure rather than sight.

Q: What is the main challenge for packaging manufacturers under these new rules?

A: The primary challenge is managing the vast complexity of global compliance. A single brand may need dozens of different pack designs—each meeting the unique warning label size, color, language, and structural rules of individual countries—all while maintaining security and efficiency in production.

Conclusion

The cigarette box is transforming from a marketing canvas into a functional public health and security device. This shift demands a highly sophisticated approach from the packaging industry. The future lies not in flashy design but in precision engineering, mandatory sustainability, and advanced security integration. Providers in this specialized field are prepared to meet these exacting demands, helping brands navigate this complex landscape by delivering packaging solutions that are compliant, secure, and future-proof.