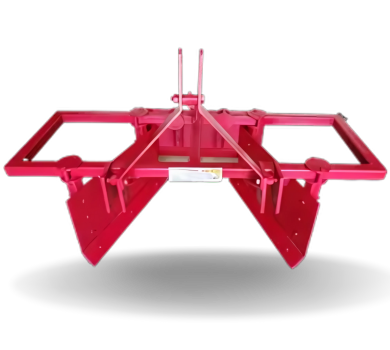

In today’s agriculture and infrastructure sectors, efficient soil and water management has become a top priority. Farmers, contractors, and land developers increasingly rely on advanced machinery to improve productivity while conserving natural resources. One such essential implement is the bund former. A reliable Bund Former Manufacturer plays a crucial role in delivering durable and precision-engineered equipment that supports sustainable farming and effective land management.

Bund former manufacturers focus on innovation, quality materials, and performance-driven designs to meet the growing demands of modern agriculture. Their machines help create strong and uniform soil bunds, improving irrigation efficiency and preventing soil erosion.

What Is a Bund Former?

A bund former is an agricultural implement used to create raised soil embankments, commonly referred to as bunds. These bunds help manage water flow, retain moisture, and protect crops from excessive runoff.

Key Functions of a Bund Former

-

Creates uniform and strong soil bunds

-

Improves water retention in fields

-

Controls irrigation flow efficiently

-

Prevents soil erosion and nutrient loss

-

Supports sustainable farming practices

A trusted Bund Former Manufacturer ensures that the equipment performs effectively across different soil types and field conditions.

Role of a Bund Former Manufacturer

A bund former manufacturer is responsible for designing, manufacturing, and supplying machines that meet the practical needs of farmers and land developers. These manufacturers combine engineering expertise with advanced production techniques to deliver long-lasting and efficient equipment.

Responsibilities of a Manufacturer

-

Designing precision-engineered bund formers

-

Using high-quality raw materials

-

Ensuring compatibility with tractors

-

Conducting quality and performance testing

-

Providing after-sales service and support

An experienced manufacturer focuses on durability, ease of operation, and customer satisfaction.

Features of High-Quality Bund Formers

A reputed Bund Former Manufacturer ensures that every bund former is built to handle demanding field conditions while delivering consistent results.

Essential Features

-

Heavy-duty steel construction

-

Adjustable bund width and height

-

Smooth soil shaping mechanism

-

Easy tractor mounting system

-

Low maintenance and long service life

These features help farmers and contractors achieve precise bund formation with minimal effort.

Benefits of Choosing a Reliable Bund Former Manufacturer

Selecting the right bund former manufacturer provides long-term benefits for agricultural and infrastructure projects.

Key Benefits

-

Consistent and uniform bund formation

-

Reduced labor and operational costs

-

Improved water conservation

-

Better soil protection and crop yield

-

Durable equipment with long lifespan

High-quality bund formers help optimize land use while improving overall productivity.

Applications of Bund Formers

Bund formers manufactured by experienced companies are used across multiple industries where soil and water management is essential.

Common Applications

-

Agricultural fields and farms

-

Irrigation and canal construction projects

-

Landscaping and land development

-

Soil conservation and watershed projects

-

Horticulture and plantation farming

Their versatility makes bund formers an indispensable tool for modern land preparation.

Types of Bund Formers Manufactured

A leading Bund Former Manufacturer usually offers a wide range of bund formers to meet diverse customer requirements.

Popular Types

-

Tractor-mounted bund formers

-

Adjustable bund formers

-

Heavy-duty bund formers

-

Hydraulic bund formers

-

Custom-designed bund formers

This variety ensures suitability for different land sizes, soil conditions, and project scales.

Manufacturing Standards and Quality Control

Quality control is a top priority for every reliable bund former manufacturer. Strict standards are followed at every stage of production to ensure durability and safety.

Quality Assurance Measures

-

Use of premium-grade steel

-

Precision welding and fabrication

-

Load and performance testing

-

Corrosion-resistant surface coatings

-

Compliance with industry standards

These measures ensure consistent performance and long-term reliability in the field.

How to Choose the Right Bund Former Manufacturer

Choosing the right Bund Former Manufacturer is essential for achieving the best performance and value.

Factors to Consider

-

Industry experience and reputation

-

Product range and customization options

-

Quality of materials and construction

-

Availability of spare parts and service support

-

Competitive pricing and timely delivery

A well-established manufacturer offers dependable equipment along with professional customer support.

Growing Demand for Bund Former Manufacturers

With increasing awareness of sustainable agriculture and water conservation, the demand for bund formers is steadily increasing. Government initiatives, modern irrigation practices, and infrastructure development projects are further driving the need for efficient soil management equipment.

Technological advancements continue to help bund former manufacturers improve machine efficiency, durability, and ease of use.

Conclusion

A reliable Bund Former Manufacturer plays a vital role in supporting modern agriculture, irrigation, and land development projects. By providing durable, precision-engineered, and efficient bund formers, manufacturers help improve soil conservation, water management, and overall productivity. Choosing the right manufacturer ensures consistent performance, long equipment life, and sustainable outcomes for farming and infrastructure operations.