Small components play an important role when you need to secure pipes and cables and ductwork. A strong band keeps everything tight and secure. A weak one can lead to damage, noise or even system failure. The advantages of using a dependable steel perforated band manufacturer show their value through actual results.

What Is a Steel Perforated Band?

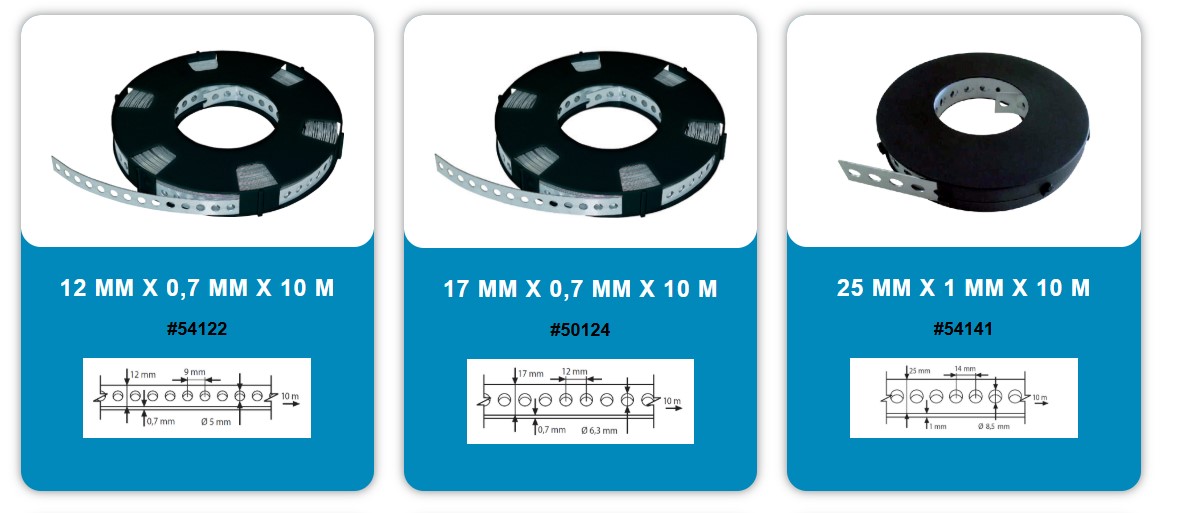

The steel perforated band consists of a flat metal strip which contains identical spaced holes throughout its length. The holes in the band allow users to create custom sizes while they can use screws or bolts to secure the band. The product delivers straightforward operation together with flexible performance which enables users to use it in any location.

You can use the product to create curved shapes which fit around pipes, poles and frames. You can install it on both walls and ceilings. The product functions effectively in residential spaces, industrial facilities, agricultural areas and major construction sites.

The design follows a fundamental structure. The critical job needs to be performed by the system.

Why Quality Matters

Not all bands are made the same. The thickness of the steel, the size of the holes, and the finish on the surface all affect strength and life span.

A reliable fixing band manufacturer focuses on:

- Strong raw steel

- Clean, even hole spacing

- Smooth edges

- Rust protection

If the band cracks when bent, it is a problem. If it rusts too fast, it is a cost. If holes are not aligned, fitting becomes slow and hard.

Good bands save time on site. They reduce waste. They lower risk.

Stainless Steel Fixing Band for Tough Conditions

The best solution for wet and harsh environments requires the use of a stainless steel fixing band. The material stainless steel maintains its original state because it does not permit rust to form. Outdoor applications and marine environments and food production facilities require materials that can withstand all these environmental conditions. The space appears tidy because of its clean appearance. The requirement becomes essential for all visible installations. The increased expense of stainless steel compared to mild steel brings about long-term benefits through extended material lifespan. The extended period will result in reduced expenses for maintenance and equipment replacement.

Common Uses

Steel perforated bands are used in many fields:

- Pipe support in plumbing systems

- Cable fixing in electrical work

- Duct support in HVAC systems

- Sign mounting

- Fence and post fixing

Installers like them because they are easy to cut and shape. You do not need heavy tools. A simple cutter and fasteners are enough.

This makes them a smart option for quick repairs and large builds alike.

Key Features to Look For

When choosing a steel perforated band manufacturer, check a few key points.

Material Grade

Ask what type of steel is used. For stainless steel fixing band, grades like AISI 304 or 316 are common. Grade 316 works better in coastal areas.

Thickness and Width

Thicker bands carry more load. Wider bands spread force better. Pick the size based on the weight you need to hold.

Surface Finish

Galvanized steel adds rust protection. Stainless steel offers natural resistance. The right finish extends service life.

Hole Pattern

Uniform holes allow easy and secure fastening. Poor spacing can weaken the band.

Benefits of Working With an Experienced Manufacturer

An experienced fixing band manufacturer does more than supply metal strips.

They test strength.

They control quality.

They offer custom sizes if needed.

They keep stock ready for fast delivery.

This support helps contractors stay on schedule. It also gives peace of mind that the product will perform as expected.

Clear specs and steady quality reduce site issues. That keeps projects moving.

Safety and Load Considerations

Always match the band to the load. Overloading can cause bending or failure.

Check load ratings. Use proper screws or bolts. Make sure anchors in walls or ceilings are strong enough.

A strong stainless steel fixing band will not fix weak anchors. The full system must be sound.

Taking a few extra minutes to plan can prevent costly damage later.

Final Thoughts

The basic design of steel perforated bands serves an important function within various systems. The bands function as connectors for different building projects, ranging from minor home fixes to massive industrial construction work. The selection of a suitable steel perforated band manufacturer guarantees customers access to products with exceptional strength and durability and extended operational lifespan.

The selection of appropriate material and thickness and finish serves as protection for your work. The fixing and support systems require strength as an essential requirement. The presence of strength is mandatory for these systems.