Rolling tobacco enthusiasts in Australia often seek ways to enhance flavor, smoothness, and burn quality at home. Proper curing transforms fresh leaves into a premium product ready for rolling, but mistakes can lead to harsh smoke or spoilage. This guide outlines essential dos and don’ts to cure & buy rolling tobacco effectively, drawing on established agricultural practices for optimal results.

Understanding Tobacco Curing Basics

Curing tobacco involves controlled drying and chemical changes in the leaf after harvest. The process includes wilting, yellowing, coloring, and drying, which develop aroma, reduce bitterness, and stabilize nicotine levels. For rolling tobacco, air-curing suits most varieties grown or sourced in Australia, producing low-sugar leaves with a light, sweet profile ideal for hand-rolled cigarettes.

Air-curing hangs leaves in ventilated spaces over four to eight weeks, allowing natural air flow to dry them evenly. This method works well for burley and cigar-type tobaccos common in home setups. Flue-curing or fire-curing may apply to specific blends, but they require precise heat control to avoid over-drying.

Do: Harvest at Peak Maturity

Select leaves when they reach full size and color, typically 4-6 weeks after flowering. Prime leaves from the middle of the plant offer the best balance of thickness and flavor for rolling tobacco. Harvest in dry weather to minimize moisture on the leaves, which prevents mold during curing.

Cut or pull leaves carefully to avoid tears, as damaged leaves cure unevenly. Handle them by the stems and transport them immediately to a curing area. This step ensures the natural sugars and oils remain intact for a smoother final product.

Do: Prepare a Suitable Curing Environment

Set up a well-ventilated barn, shed, or enclosed space with good air circulation. In Australia, use a location shielded from direct sun, rain, and extreme humidity, aiming for 60-70% relative humidity initially. String leaves on poles or hang them individually with stems up, spaced 10-15 cm apart for airflow.

Maintain temperatures between 20-30°C during early stages, gradually lowering as drying progresses. Fans on low speed help, but avoid strong drafts that dry leaves too quickly. Monitor daily with a hygrometer to adjust conditions.

Do: Follow the Four-Stage Curing Process

Start with wilting: Let leaves soften for 24-48 hours until pliable. Yellowing follows over 3-5 days, where chlorophyll breaks down into pleasant aromas; keep humidity high.

Progress to coloring, which takes 1-2 weeks, turning leaves brown while preserving oils. Finish with drying over several weeks until stems snap crisply. Rotate bundles weekly for even exposure. Patience here yields tobacco with superior burn and taste.

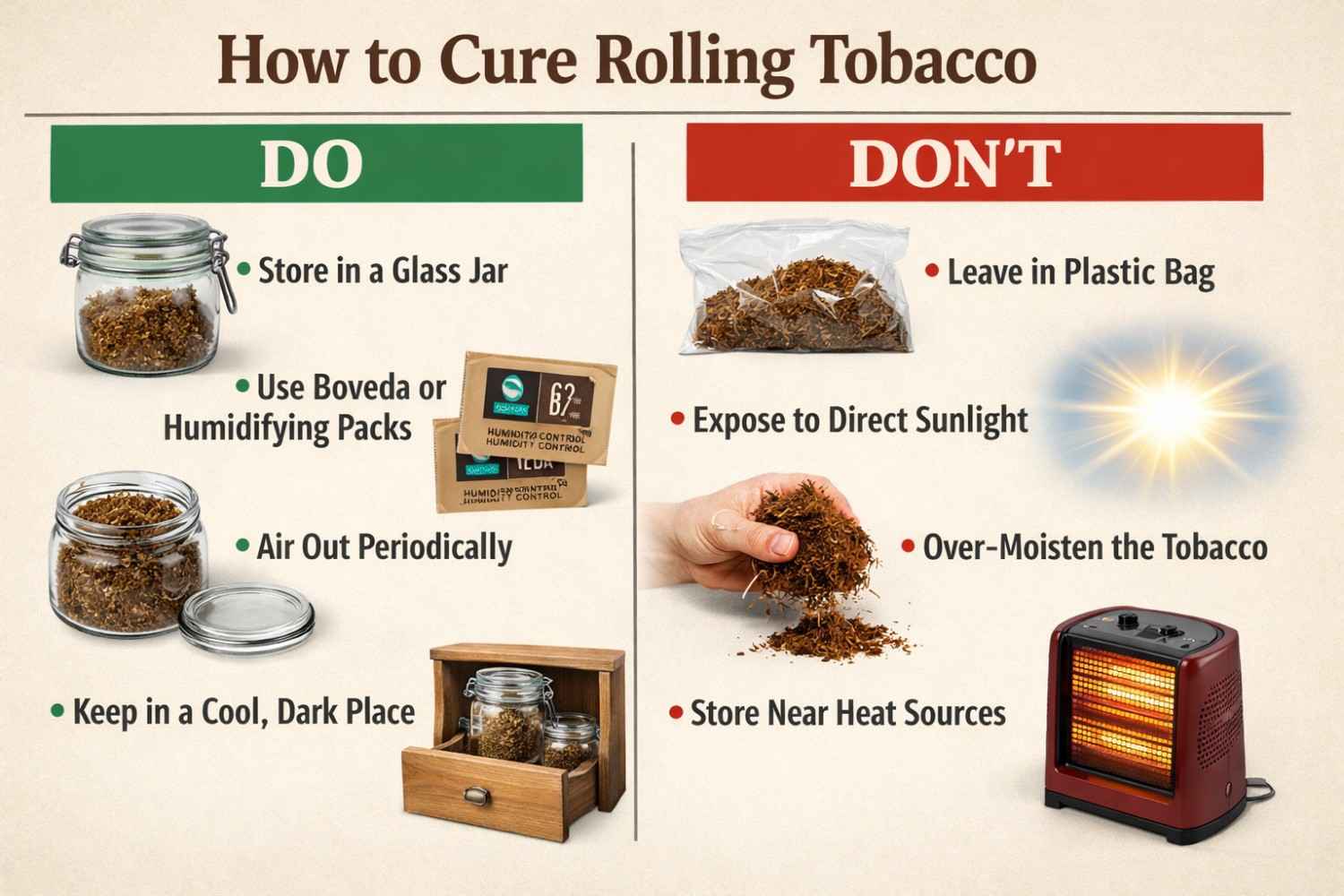

Do: Age the Cured Tobacco

After drying, bundle leaves in breathable cloth and store in airtight containers for 6-12 months. This aging phase allows further oxidation, mellowing harshness and enhancing smoothness for rolling. Check monthly for pests or excess moisture, and re-dry if needed.

In Australia’s variable climate, use cool, dark spaces like cupboards. Aged tobacco rolls easier and delivers consistent flavor, making it worth the wait.

Don’t: Rush the Drying Process

Fast drying with high heat or direct sunlight scorches leaves, destroying sugars and creating bitter smoke. Artificial dryers often overdo this, leading to brittle tobacco unsuitable for rolling. Allow natural progression; rushing skips critical chemical changes.

Don’t: Ignore Humidity and Ventilation Balance

Too much moisture invites mold, common in humid Australian regions. Black spots or fuzz signal spoilage; discard affected leaves immediately. Conversely, overly dry air cracks leaves, reducing elasticity for poor rolls.

Avoid sealed plastic bags early on; they trap moisture. Opt for wooden frames or mesh in open barns instead.

Don’t: Overcrowd or Mishandle Leaves

Packing leaves tightly blocks air flow, causing uneven curing and rot. Maintain space between each leaf to let moisture escape gradually. Rough handling bruises tissues, releasing unwanted enzymes that sour the flavor.

Skip stacking wet leaves; always wilt first. Clean tools and surfaces prevent contamination from bacteria or pests.

Don’t: Neglect Pest and Mold Checks

Insects like tobacco beetles thrive in warm conditions; inspect weekly and remove infested leaves. Use natural deterrents like cedar blocks rather than chemicals, which taint taste.

High humidity spikes during Australian wet seasons demand extra vigilance. If mold appears, increase ventilation promptly to salvage the batch.

Do: Test for Readiness Before Rolling

Cured tobacco feels leathery, with flexible stems and a rich tobacco scent. Shred a small sample, roll, and smoke-test; it should burn evenly without harshness. Adjust re-curing if too moist or moisten slightly with a humidifier pack for storage.

Properly cured leaves shred finely for perfect rolls, avoiding waste or uneven burns.

Advanced Tips for Australian Rollers

Adapt to local climates: In drier areas like inland NSW, add humidity trays; coastal growers prioritize ventilation. Experiment with hybrid methods, like partial sun-drying for aromatic blends, but monitor closely. Blend cured varieties post-aging for custom flavors suited to Australian preferences.

Track batches with notes on harvest date, conditions, and outcomes to refine future cures. This builds expertise over seasons.

Common Mistakes and Fixes

|

Mistake |

Consequence |

Fix |

|

Harvesting too early |

Weak flavor, high sugar |

Wait for yellowing base leaves. |

|

Poor ventilation |

Mold growth |

Space leaves, use fans. |

|

Skipping aging |

Harsh smoke |

Store 6+ months. |

|

High heat exposure |

Scorched taste |

Maintain 20-30°C. |

|

Wet storage |

Rot |

Dry fully first. |

Mastering these dos and don’ts elevates home-cured rolling tobacco to professional quality. For premium, ready-to-use options that skip the hassle, consider trusted suppliers like My Cigs Australia. They offer high-grade products perfect for Australian rollers seeking convenience and consistency.