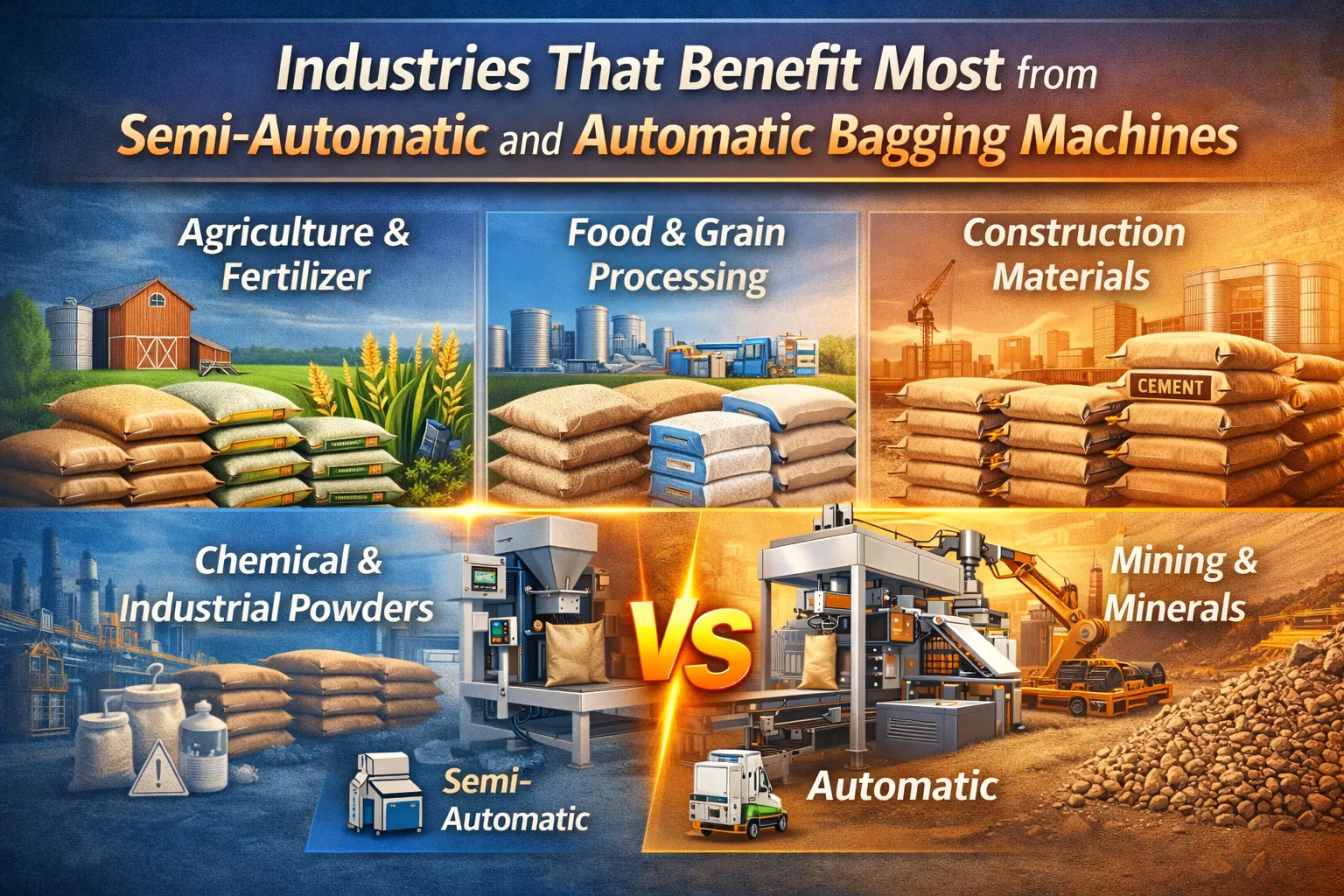

As packaging demands increase across manufacturing and processing industries, businesses are under constant pressure to improve speed, accuracy, and cost efficiency. This is where semi-automatic bagging machines and automatic bagging machines play a critical role. Choosing the right bagging solution is not just about automation—it’s about aligning machine capability with industry-specific production needs.

In this guide, we explore the key industries that benefit most from semi-automatic and automatic bagging machines, how each system fits different operational scales, and why investing in the right solution from GLZON can directly impact productivity and profitability.

Why Industry-Specific Bagging Solutions Matter

Not all industries handle the same materials, bag sizes, or production volumes. Factors such as product flowability, dust control, weight accuracy, and throughput requirements vary widely. That’s why manufacturers often choose between semi-automatic bagging systems and fully Auto Bagging Machines based on:

-

Daily production volume

-

Labor availability

-

Material type (granular, powder, flakes, pellets)

-

Required bag weights and formats

-

Compliance and safety standards

Understanding how each industry uses bagging technology helps businesses make smarter, ROI-driven decisions.

Agriculture & Fertilizer Industry

Packaging Needs

The agriculture sector handles large volumes of materials such as:

-

Seeds

-

Fertilizers

-

Animal feed

-

Grain and pulses

Best-Fit Machines

-

Semi-automatic bagging machines are ideal for medium-scale fertilizer plants and feed mills where manual bag placement is acceptable.

-

Automatic bagging machines are preferred for high-volume fertilizer and seed producers needing consistent weight accuracy and dust-free operation.

Automated systems reduce spillage, improve batch consistency, and ensure compliance with export-grade packaging standards. Many agribusinesses rely on GLZON bagging machines for their durability and ability to handle abrasive materials.

Food & Grain Processing Industry

Packaging Needs

Food processors require precision, hygiene, and consistency when packaging:

-

Rice

-

Wheat

-

Flour

-

Sugar

-

Pulses and lentils

Best-Fit Machines

-

Semi-automatic bagging systems work well for regional mills and specialty food producers.

-

Auto Bagging Machines are essential for large-scale grain processors where speed, cleanliness, and minimal human contact are critical.

Advanced weighing systems and stainless-steel options make GLZON bagging machines suitable for food-grade operations while maintaining high throughput.

Cement, Construction & Building Materials

Packaging Needs

Construction materials are heavy, dusty, and produced in bulk, including:

-

Cement

-

Sand

-

Fly ash

-

Mortar and gypsum

Best-Fit Machines

-

Automatic bagging machines dominate this industry due to high production rates and labor reduction.

-

Semi-automatic machines are often used by smaller suppliers or mobile plants.

Automated bagging ensures faster truck loading, reduced material loss, and consistent bag weights—critical for maintaining brand trust in construction supply chains.

Chemical & Industrial Powder Industry

Packaging Needs

Chemical manufacturers package:

-

Industrial powders

-

Additives

-

Pigments

-

Minerals and compounds

Best-Fit Machines

-

Semi-automatic bagging machines suit controlled, lower-volume environments requiring operator supervision.

-

Automatic bagging systems are used where safety, enclosure, and dust extraction are top priorities.

With advanced control systems and sealed filling mechanisms, GLZON bagging machines help chemical plants improve worker safety while increasing packaging efficiency.

Plastic, Polymer & Resin Manufacturing

Packaging Needs

Plastic and polymer industries deal with:

-

Plastic granules

-

Polymer resins

-

Masterbatch materials

Best-Fit Machines

-

Auto Bagging Machines are highly preferred due to continuous production lines and uniform product flow.

-

Semi-automatic systems may be used for specialty or low-volume resin products.

Automated bagging ensures consistent fill weights, clean packaging, and seamless integration with conveyors and palletizers.

Mining & Minerals Industry

Packaging Needs

Mining operations require robust machines for:

-

Minerals

-

Ores

-

Silica sand

-

Lime and aggregates

Best-Fit Machines

-

Automatic bagging machines handle high-capacity, rugged environments.

-

Semi-automatic systems are suitable for remote or smaller-scale mining operations.

Heavy-duty construction and precise weighing make GLZON bagging machines reliable even in harsh industrial conditions.

E-Commerce, Logistics & Warehousing

Packaging Needs

This fast-growing sector focuses on:

-

Speed

-

Accuracy

-

Reduced manual handling

Best-Fit Machines

-

Auto Bagging Machines are widely used for high-speed order fulfillment.

-

Semi-automatic machines support smaller warehouses transitioning toward automation.

Automated bagging improves order accuracy and reduces packing time, directly impacting customer satisfaction.

Choosing the Right Bagging Machine for Your Industry

When selecting between semi-automatic and automatic systems, businesses should consider:

-

Production volume per hour

-

Type and flow characteristics of material

-

Available labor and skill level

-

Budget and long-term ROI

-

Integration with existing production lines

Exploring modern Auto Bagging Machines can help industries scale faster while lowering operational costs.

Why Industries Trust GLZON Bagging Machines

Across agriculture, construction, food processing, chemicals, and plastics, manufacturers rely on GLZON bagging machines for:

-

Industrial-grade build quality

-

Accurate and consistent weighing

-

Flexible automation levels

-

Easy maintenance and scalability

-

Global industry compatibility

By offering both semi-automatic and fully automated solutions, GLZON enables businesses to grow without changing their entire packaging infrastructure.

👉 Explore the complete range of GLZON bagging machines to find the perfect fit for your industry and production goals.