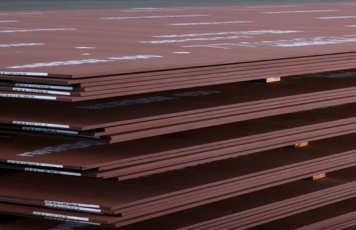

In industries where machinery and equipment are exposed to extreme abrasion, impact, and pressure, material quality becomes a critical factor for operational success. NM 500 steel plates are engineered to deliver exceptional wear resistance and strength in such demanding environments. Partnering with a reliable NM 500 plate supplier ensures access to premium-quality plates that enhance equipment lifespan, reduce downtime, and improve overall productivity. These plates are widely used across mining, construction, cement, and heavy engineering sectors due to their outstanding performance.

Understanding NM 500 Steel Plates

NM 500 is a high-strength, wear-resistant steel plate known for its hardness of approximately 500 Brinell (HBW). This high level of hardness allows the plate to withstand severe abrasion while maintaining sufficient toughness to handle impact loads. A professional NM 500 plate supplier provides plates manufactured under controlled processes to ensure consistent mechanical properties and reliable performance.

Key properties of NM 500 steel plates include:

-

Excellent abrasion and wear resistance

-

High impact strength under heavy working conditions

-

Uniform hardness across the surface

-

Good weldability with proper techniques

-

Long operational life compared to conventional steel

These properties make NM 500 steel plates suitable for heavy-duty applications.

Importance of Choosing the Right NM 500 Plate Supplier

Selecting the right NM 500 plate supplier is crucial for industries that depend on uninterrupted operations. Inferior-quality plates can wear out quickly, leading to increased maintenance costs and unexpected shutdowns.

Advantages of working with a trusted supplier include:

-

Guaranteed material quality with mill test certificates

-

Consistent thickness and dimensional accuracy

-

Compliance with international quality standards

-

Reliable inventory and timely delivery

-

Technical guidance for fabrication and application

An experienced NM 500 plate supplier understands industry challenges and delivers solutions that match specific operational needs.

Industrial Applications of NM 500 Steel Plates

NM 500 plates sourced from a reliable NM 500 plate supplier are used in applications where resistance to wear and impact is essential.

Common applications include:

-

Mining equipment liners and wear parts

-

Crusher liners, feeders, and chutes

-

Dump truck bodies and excavator buckets

-

Cement plant machinery and clinker handling systems

-

Quarry and aggregate processing equipment

-

Material handling and earthmoving machinery

These industries rely on NM 500 plates to maintain efficiency under continuous stress.

Benefits of Using NM 500 Steel Plates

Working with a dependable NM 500 plate supplier allows businesses to maximize the benefits of NM 500 steel.

Major benefits include:

-

Extended service life of components

-

Reduced downtime and maintenance frequency

-

Improved equipment reliability

-

Lower replacement and labor costs

-

Enhanced productivity in high-wear environments

NM 500 plates are designed to outperform standard carbon steel, making them a cost-effective solution in the long term.

Product Range and Services Offered by NM 500 Plate Suppliers

A professional NM 500 plate supplier offers a wide selection of plates and value-added services to meet diverse industrial requirements.

Typical offerings include:

-

Various thicknesses and custom dimensions

-

Profile cutting, bending, and machining services

-

Shot blasting and surface treatment options

-

Bulk supply for large-scale industrial projects

-

Fast dispatch for urgent operational needs

These services help clients receive NM 500 plates tailored to their exact specifications.

Quality Control and Testing Standards

Quality assurance is a critical aspect of any reputable NM 500 plate supplier. Each plate undergoes rigorous testing to ensure it meets performance and safety standards.

Quality checks generally include:

-

Chemical composition analysis

-

Hardness and tensile strength testing

-

Ultrasonic and surface inspections

-

Dimensional tolerance verification

-

Certification with mill test reports

These procedures guarantee that NM 500 plates perform consistently in extreme conditions.

Industries Served by NM 500 Plate Suppliers

An experienced NM 500 plate supplier caters to a wide range of heavy industries that operate in abrasive environments.

Industries served include:

-

Mining and mineral processing

-

Construction and infrastructure development

-

Cement and power generation plants

-

Heavy engineering and fabrication units

-

Bulk material handling and logistics

Supplying to these sectors requires technical expertise, reliable sourcing, and a strong distribution network.

Why NM 500 Plates Are a Smart Investment

Although NM 500 plates have a higher initial cost, sourcing from a trusted NM 500 plate supplier ensures long-term financial benefits. Their superior wear resistance reduces the frequency of replacements and maintenance.

Long-term advantages include:

-

Lower operational and maintenance costs

-

Improved equipment uptime

-

Reduced material wastage

-

Increased overall efficiency

This makes NM 500 steel plates an ideal choice for industries seeking durability and performance.

Conclusion

Partnering with a reliable NM 500 plate supplier is essential for industries that require high-performance, wear-resistant steel solutions. NM 500 plates provide exceptional hardness, durability, and impact resistance, making them suitable for the most demanding industrial applications. With consistent quality, comprehensive testing, and dependable supply, a professional NM 500 plate supplier helps businesses enhance productivity, reduce costs, and achieve long-term operational success.