The landscape of cigarette packaging is undergoing a remarkable transformation. With tighter laws, growing environmental responsibility, and advances in technology, the industry is being pushed toward smarter, more sustainable, and regulation-compliant solutions. This blog explores how these shifts are redefining the way cigarette packaging is designed, produced, and perceived around the world.

Adapting to a New Era of Packaging

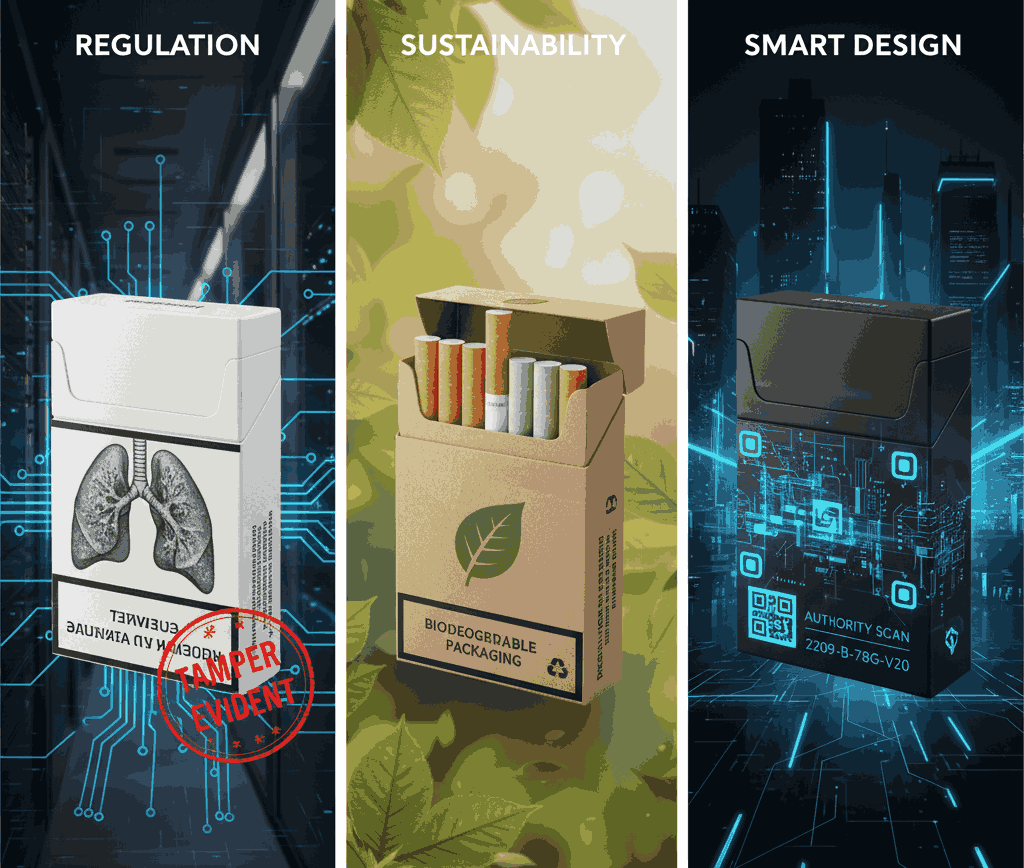

In an era where packaging design is heavily influenced by policy, cigarette manufacturers and packaging experts face new challenges and opportunities. The focus has shifted from traditional branding to compliance, sustainability, and authenticity, the three pillars shaping the next generation of cigarette boxes.

1. The Global Movement Toward Standardized Design

The transition to plain packaging is one of the most significant regulatory developments in recent years.

-

Reducing Promotional Influence: Regulations now restrict the use of colors, logos, and decorative fonts to curb the appeal of cigarettes, particularly among younger audiences.

-

Emphasizing Health Awareness: Graphic health warnings dominate the packaging surface, leaving limited room for any brand distinction.

-

Wider Implementation: Plain packaging requirements have extended to vape products, e-cigarettes, and heated tobacco items, forcing manufacturers to re-engineer packaging across all categories.

2. Environmental Responsibility Takes Center Stage

Sustainability has become a defining value in modern packaging. As both governments and consumers prioritize eco-friendly practices, tobacco packaging is evolving toward greener materials and efficient design.

-

Sustainable Substrates: Manufacturers are replacing conventional materials with recycled, biodegradable, and compostable options.

-

Optimized Production: Reducing material thickness, minimizing waste, and improving recyclability are now key considerations at every stage of development.

3. Strengthening Packaging Security

As branding elements disappear, packaging has taken on a new purpose protecting authenticity and preventing counterfeiting.

-

Built-in Security Layers: Advanced printing methods, serialized QR codes, invisible inks, and holographic foils are being integrated to safeguard products.

-

Comprehensive Tracking Systems: Digital traceability tools help monitor the product journey from factory to consumer, ensuring transparency and accountability.

Challenges for Manufacturers in a Changing Landscape

Navigating Complex Regulations

Each country applies its own standards for cigarette packaging from warning size to color specifications. Manufacturers must stay informed and agile to ensure every design meets its destination’s legal framework.

Designing Within Restrictions

While creativity is limited, innovative approaches to texture, structure, and functionality can still enhance consumer experience and maintain quality perception.

Balancing Green Goals and Cost Efficiency

Eco-friendly materials and high-tech security elements often add to production costs. The key lies in integrating sustainability without compromising affordability.

New Technologies and Design Innovations

Despite strict guidelines, innovation in cigarette packaging is thriving behind the scenes.

-

Digital Printing Revolution: Modern printing technologies allow for precision coding, localized compliance data, and efficient short runs, minimizing excess inventory and waste.

-

Smart Connectivity: Features such as QR or NFC tags provide instant access to product verification and recycling information, bridging the gap between compliance and transparency.

-

Functional Design Enhancements: Even subtle changes such as easy-open flaps or reinforced hard packs can improve usability and strengthen product protection.

Frequently Asked Questions

Q: What is standardized cigarette packaging?

It’s a regulation that mandates all tobacco products to use identical colors, layouts, and fonts while removing all marketing graphics. This ensures uniformity and promotes public health messaging.

Q: Are sustainable materials required for tobacco packaging?

Not globally, but many regions now encourage or enforce eco-friendly standards, pushing brands toward recyclable, biodegradable, and responsibly sourced materials.

Q: How does packaging technology fight counterfeiting?

Security printing, traceable serial numbers, holographic details, and tamper-evident features make it far more difficult for counterfeiters to replicate or distribute illegal products.

Conclusion

Cigarette packaging has entered a new age, one defined by transparency, compliance, and innovation. Instead of focusing on visual marketing, the industry is now prioritizing environmental impact, product security, and regulatory integrity.

For modern packaging providers, this transformation represents more than a challenge, it’s an opportunity to innovate responsibly, protect products, and contribute to a more sustainable future for the tobacco industry.