A reliable perforated band manufacturer plays a key role in modern fixing work. These bands help secure pipes, cables, ducts, and frames with steady support. They are simple in design but strong in use. Many installers prefer them because they adjust easily and hold firm. A well-made band reduces install time and improves safety on site. This makes perforated bands a trusted choice across many trades.

What is a Perforated Band?

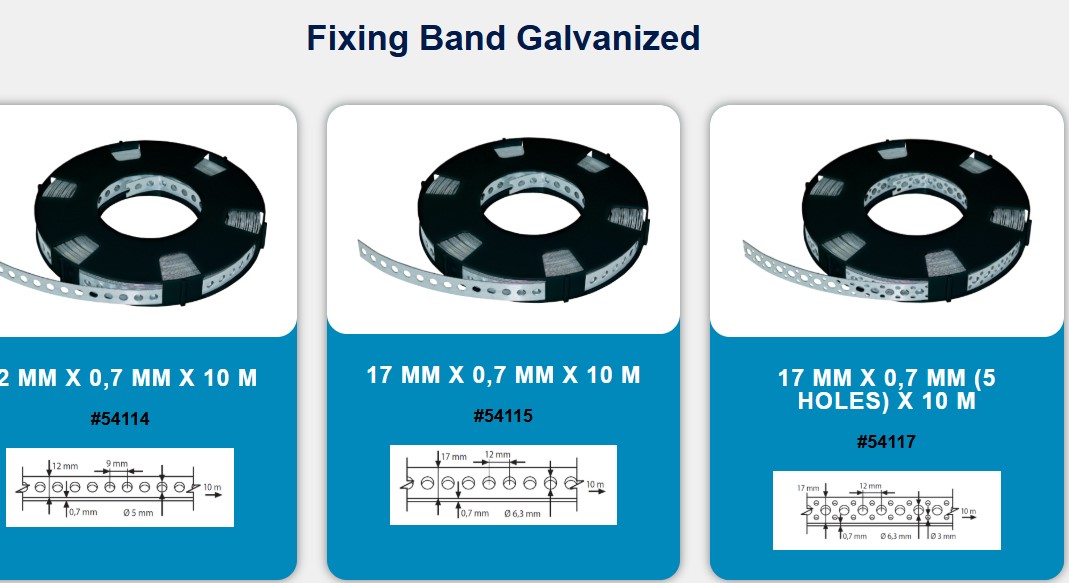

A perforated band is a steel strip with evenly spaced holes along its length. These holes allow quick fastening with screws or bolts. The design removes the need for cutting tools in most cases. Installers can select the right hole and tighten the band in place. This saves effort during setup and repairs. The result is a clean, tight fix that stays secure under load.

Steel is the most common material used for perforated bands. It offers high strength and good bend control. Steel resists pull and twist better than many other materials. This makes it suitable for both light and heavy fixing tasks. A steel perforated band manufacturer selects steel that balances strength with ease of shaping. This balance helps workers bend the band without cracking or losing grip.

Many industries rely on perforated fixing bands every day. In plumbing work, they hold pipes against walls or ceilings. In electrical jobs, they secure cable runs in neat lines. HVAC teams use them to support ducts and vents. Builders also use them for light bracing and frame support. This wide use shows how flexible and useful the product is.

How is steel perforated band manufactured?

The production process of fixing bands affects their quality and safety. Steel sheets are first cut into narrow strips with accurate width. Machines then punch holes at equal spacing. This step is important because uneven holes can weaken the band. After punching, edges are smoothed to prevent cuts during handling. Bands then move to coating or finishing stages. Each batch is checked before packing.

Surface finish plays a big role in how long a band lasts. Zinc coated bands help resist rust in both indoor and outdoor areas. Stainless steel bands suit places with high moisture or chemical exposure. Plain steel bands work well in dry indoor settings. Choosing the right finish helps extend service life. It also keeps the installation safe and neat over time.

Working directly with a perforated band manufacturer brings clear benefits. Quality stays consistent across all orders. Sizes and hole patterns remain uniform, which helps with planning. Manufacturers can also offer custom sizes when needed. This supports special projects without long delays. Bulk supply from the source often reduces overall cost.

What to look for in the right perforated band?

Strength and flexibility must stay in balance for fixing bands. A band that is too stiff becomes hard to shape on site. This can lead to stress on fasteners or surfaces. A band that is too soft may lose tension over time. Skilled fixing band manufacturers test this balance during production. They ensure bands bend smoothly while holding firm. This helps maintain safety during long use.

Ease of installation is another key reason for the popularity of perforated bands. Workers can install them with basic tools. The holes guide screw placement and spacing. Adjustments are simple by shifting to a different hole. This makes alignment faster and more accurate. A tidy installation also improves the look of the finished work.

Quality control is a major part of reliable manufacturing. Each fixing band must meet set rules for size and strength. Checks help spot weak areas or sharp edges. Even hole spacing ensures equal load spread along the band. Trusted manufacturers keep records for each batch. This supports traceability and steady product standards.

Perforated bands serve projects of all sizes across Europe. They are used in homes, offices, factories, and public buildings. Demand stays strong due to their wide range of uses. Suppliers like FixingBand.eu support this demand with ready stock. Quick supply helps keep projects on schedule. Reliable delivery builds long term trust with clients.

Conclusion

Choosing the right fixing band partner matters for project success. Buyers should look for clear material options and finishes. Product range and size choices also matter. It helps to ask about testing and quality steps. A good fixing band manufacturer offers guidance before purchase. They help match the band to the task at hand.

Perforated fixing bands remain a simple yet vital solution in construction and maintenance work. Their strength, ease of use, and low cost add clear value. Steel bands support many trades without complex tools. Choosing the right steel perforated band manufacturer ensures lasting performance. Quality bands improve safety and reduce future repairs. They help deliver strong and reliable results on every job.