Industrial operations generate significant carbon dioxide from combustion, welding, fermentation, and confined worker spaces, creating persistent air quality challenges that exceed OSHA limits above 5000 parts per million. Elevated concentrations impair worker performance, increase accident risks, and necessitate shutdowns during emergencies. This comprehensive guide examines all major CO2 removal system types suitable for factories, refineries, and processing plants, detailing mechanisms, applications, advantages, and selection criteria for optimal safety and compliance.

Carbon Dioxide Generation in Industrial Settings

Processes such as gas-fired boilers, arc welding, and chemical reactions release carbon dioxide alongside worker exhalation of approximately 1 kilogram per person daily. In enclosed 500 cubic meter facilities with 20 workers, concentrations reach 1 percent within hours, causing fatigue, headaches, and reduced decision-making capacity. Levels at 5 percent trigger respiratory distress, while 10 percent leads to unconsciousness. Traditional exhaust systems risk pulling in external contaminants, and particulate filters fail to address gaseous buildup.

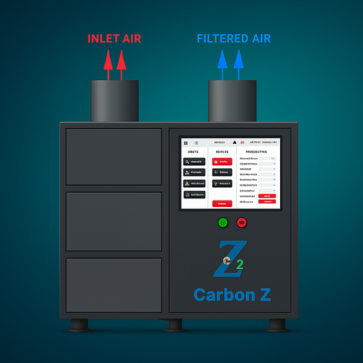

CO2 removal systems capture and process this gas through chemical or physical means, recirculating purified air internally while maintaining overpressure to contain hazards. Industrial-grade units process 500 to 5000 cubic meters per hour, ensuring continuous safe operation.

Regenerative Adsorption CO2 Removal Systems

Regenerative adsorption systems dominate industrial applications, utilizing multiple beds filled with solid sorbents like zeolite or activated amines. Air passes through an active bed where carbon dioxide binds selectively, while saturated beds regenerate automatically via pressure swing, temperature swing, or vacuum processes, releasing pure gas for venting or reuse. Four-bed configurations enable nonstop operation, with one bed scrubbing while others cycle through regeneration phases every four to eight hours.

These systems achieve 95 percent capture efficiency, handling high loads from welding bays or boiler rooms. Power consumption stays under 2 kilowatts for 1000 cubic meter per hour units, with modular scaling for large plants. Annual media regeneration costs approximately $1000, providing unmatched uptime for 24/7 facilities.

Chemical Absorption CO2 Removal Systems

Chemical absorption employs liquid solvents such as monoethanolamine (MEA) or proprietary blends in packed towers where flue or process gases contact the solution. Carbon dioxide reacts chemically to form stable compounds, scrubbed from the stream with regeneration occurring through steam stripping in a separate column. Industrial variants process thousands of cubic meters per hour, capturing 90 percent of emissions from stacks or confined spaces.

Common in refineries and power plants, these systems integrate with existing ductwork but require corrosion-resistant materials and higher energy for solvent reboiling. Maintenance involves solvent replacement every two years and pH monitoring to prevent degradation. Capital costs range from $50,000 for compact units to millions for full plant integration.

Membrane Separation CO2 Removal Systems

Membrane systems force gas mixtures through selective polymer or ceramic barriers that permit carbon dioxide passage while retaining oxygen, nitrogen, and other components. High-pressure feed streams achieve 80 to 90 percent purity output, suitable for pre-concentrated industrial exhausts rather than ambient air. Spiral-wound or hollow-fiber configurations scale easily for factory ventilation.

Advantages include compact footprints occupying one-tenth the space of absorption towers and no moving parts for minimal maintenance. Drawbacks involve moderate selectivity requiring multi-stage setups and sensitivity to contaminants like sulfur compounds. Deployment thrives in natural gas processing and food-grade carbon dioxide recovery, with 2025 models incorporating advanced polymers boosting efficiency 20 percent.

Cryogenic Distillation CO2 Removal Systems

Cryogenic systems cool gas streams to minus 100 degrees Celsius or lower, liquefying carbon dioxide at its phase change point while other gases remain vapor. Multi-stage compression, heat exchange, and distillation towers achieve 99 percent purity for industrial sale or sequestration. Large-scale units handle brewery fermentation or cement kiln exhausts exceeding 10,000 cubic meters per hour.

High energy demands for refrigeration limit applications to facilities with byproduct revenue streams, but zero chemical usage appeals for clean processes. Maintenance focuses on heat exchanger cleaning and compressor servicing, with installations costing $1 million plus for high-capacity models.

Biological and Hybrid CO2 Removal Systems

Emerging biological systems cultivate algae or bacteria in photobioreactors that metabolize carbon dioxide into biomass, integrated with wastewater treatment or biofuel production. Hybrid electro-swing adsorption combines electrical fields with sorbents for low-energy regeneration, suitable for intermittent industrial loads. These gain traction in green chemistry plants prioritizing sustainability credentials.

Biological variants require controlled lighting and nutrients but offer carbon-negative potential when biomass sequesters durably. Hybrids provide flexibility for variable flows, with pilot installations demonstrating 85 percent removal at 500 watts per cubic meter processed.

Selection Criteria for Industrial CO2 Removal Systems

Match system type to gas stream characteristics including concentration, pressure, temperature, and contaminants. High-purity needs favor cryogenics, while continuous uptime demands regeneratives. Energy budgets under 0.2 kilowatt-hours per kilogram captured prioritize membranes or hybrids. Space constraints steer toward compact adsorption or membrane solutions, while regulatory compliance requires verifiable capture rates above 90 percent.

Lifecycle analysis weighs $20,000 to $2 million capital against $0.50 to $5 per ton operating costs, factoring maintenance intervals and byproduct value. Pilot testing confirms performance under site-specific conditions.

Installation and Integration Considerations

Duct high-volume systems into existing HVAC at 100-to-300-millimeter diameters, ensuring gastight seals with industrial gaskets. Electrical panels demand 3-phase 480-volt feeds with surge protection. SCADA connectivity enables centralized control alongside fire and gas detection systems. Commissioning spans 72 hours of load testing to calibrate sensors and validate capture efficiency.

Operational and Maintenance Best Practices

Daily digital logs track performance metrics, with weekly filter inspections preventing blockages. Quarterly full-load simulations stress-test under peak production. Annual professional servicing regenerates media or replaces membranes, budgeted at 5 percent of capital yearly. Remote monitoring reduces site visits by 70 percent.