Advanced performance gets claimed constantly. Every product launch promises breakthrough capabilities. Most deliver incremental improvements dressed up as revolution. Genuine advancement? That’s considerably rarer.

Real advanced performance means solving problems that previously seemed unsolvable. Achieving capabilities that weren’t feasible before. Eliminating compromises that everyone accepted as fundamental limitations.

The ESP Series delivers exactly this kind of advancement. Not through marketing exaggeration, but engineering that fundamentally rethinks what’s achievable when operational requirements push beyond conventional boundaries.

Precision That Doesn’t Collapse Under Stress

High-precision equipment traditionally operates under carefully controlled conditions. Perfect temperature stability. Minimal vibration. Gentle handling. Step outside these parameters, and accuracy evaporates.

Problem is, real operations rarely provide perfect conditions. Temperature fluctuates throughout facilities. Vibration from nearby equipment transmits through mounting structures. Production demands prevent gentle operation.

Conventional high-precision platforms require extensive environmental control or accept significant accuracy degradation. Neither option is great—environmental control gets expensive, and accuracy loss defeats the purpose of precision equipment.

The ESP platform takes a fundamentally different approach. Precision engineered to withstand realistic operational stresses rather than requiring protection from them. Thermal compensation happens automatically across temperature ranges that would throw conventional systems completely off. Mechanical isolation protects critical elements from environmental vibration without requiring special foundations. Dynamic control systems maintain accuracy even during aggressive operational movements.

Results speak clearly. Specifications maintained in regular production environments without climate control or vibration isolation. Precision holding through extended operation as components warm up. Accuracy consistent whether running gently or pushing throughput limits.

This changes what’s operationally feasible. High-precision work in normal facilities instead of specialized clean rooms. Production-rate flexibility without accuracy penalties. Real-world deployment of capabilities that previously demanded laboratory conditions.

Response Speed That Enables New Capabilities

Static precision is valuable. Dynamic precision—maintaining accuracy while responding quickly to changing demands—opens entirely new operational possibilities.

Most high-precision equipment is slow. Accelerate operations, and accuracy suffers from dynamic effects. Vibration during movement. Settling time after positioning. Thermal transients from rapid cycling. The delays accumulate, killing throughput.

The ESP architecture achieves fast dynamic response while preserving precision through sophisticated control systems and mechanical design. Structural rigidity prevents deflection during acceleration. Control loops fast enough to stabilize positioning within milliseconds. Predictive algorithms compensating for dynamic effects before they impact accuracy.

This combination—precision maintained while operating fast—enables applications that weren’t previously viable. High-throughput production requiring tight tolerances. Rapid prototyping with production-level accuracy. Flexible manufacturing handling diverse requirements without performance compromises.

Speed and precision working together instead of fighting each other. Strange how rare this capability remains despite being obviously valuable. Engineering challenge is substantial, though, which explains why most platforms still force choosing between the two.

Adaptability Without Performance Penalties

Specialized equipment does one thing extremely well. Everything else requires workarounds or different machines. Flexible equipment handles variety but compromises performance. The tradeoff seemed fundamental.

Different thinking here. The ESP platform delivers specialist-level performance across operational ranges that typically require multiple specialized systems. Configuration adapts to specific requirements while maintaining core performance characteristics.

Not about adding more features that rarely get used. It’s fundamental architecture supporting genuine operational flexibility. Control systems that optimize for different operational modes. Mechanical design accommodating varied workpiece requirements. Power and thermal systems handling diverse demand profiles.

Single platform replacing what previously required three specialized machines. Same precision, same speed, same reliability across applications conventional wisdom said needed dedicated equipment. Operational advantages compound—simplified training, reduced spare parts inventory, unified maintenance procedures.

Flexibility that actually works changes procurement strategies fundamentally. Instead of speculating about future needs and buying specialized equipment that might become obsolete, facilities can deploy platforms adapting as requirements evolve. Investment stays productive longer.

Integration That Enhances Rather Than Complicates

Advanced equipment often becomes operationally complex. More capability means more settings, more monitoring, more expertise required. The sophistication turns into burden.

Different philosophy with the ESP platform. Advanced capability shouldn’t require advanced degrees to operate. Sophistication gets handled internally through intelligent systems. Operators interact with clear interfaces providing actionable information instead of raw technical data.

Diagnostic systems identify actual problems rather than listing every minor deviation. Maintenance notifications are predictive and specific instead of generic warnings. Integration with facility systems happens through standard protocols that work reliably without constant troubleshooting.

This approach matters enormously for facilities without specialized technical staff. Equipment needs to deliver advanced performance while remaining operationally straightforward. Complexity managed internally rather than pushed onto operators who have production quotas to meet.

Training times decrease significantly. New operators become productive faster. Experienced operators spend time on value-added activities instead of constantly adjusting settings or interpreting cryptic system messages.

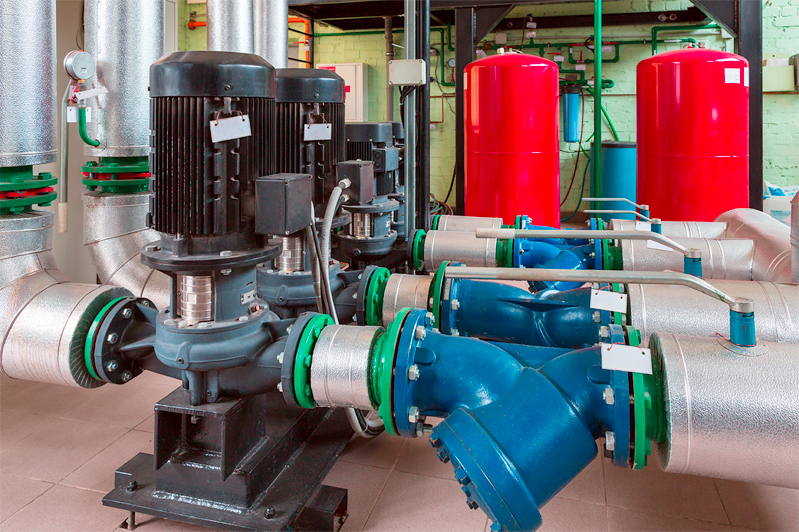

Durability Under Demanding Conditions

Advanced performance and rugged durability usually seem incompatible. High precision requires delicate construction. Robust equipment sacrifices accuracy. Choose your compromise.

The ESP approach proves this tradeoff isn’t inevitable. Durability through intelligent design rather than heavy construction. Components protected from excessive stress through sophisticated control systems. Thermal management preventing temperature extremes that accelerate degradation. Mechanical design isolating sensitive elements from harsh operational impacts.

Equipment delivers precision performance while surviving conditions that would destroy conventional high-precision platforms. Not through hoping nothing goes wrong, but through engineering that anticipates real-world operational stress and handles it without performance degradation.

Field service data demonstrates this clearly. Equipment maintaining specifications through years of demanding production use. Component replacement following predictable schedules instead of emergency interventions. Precision holding despite accumulation of operating hours that would require complete rebuilds with conventional platforms.

Total cost of ownership shifts dramatically when advanced performance doesn’t require coddling. Equipment gets deployed where capabilities are needed instead of where conditions are perfect. Operational restrictions decrease while performance benefits increase.

Comparison With Parallel Platform Approaches

The PLW Series represents another approach to advanced performance challenges, optimizing for different operational priorities while sharing recognition that conventional limitations aren’t acceptable anymore. Both platforms reflect industry movement toward comprehensive capability without traditional compromises.

Market expectations evolved significantly. Operations need equipment handling multiple challenging requirements simultaneously under realistic conditions. Advanced performance in controlled laboratory settings doesn’t serve modern operational needs.

Procurement specifications increasingly emphasize sustained real-world capability over peak performance under ideal conditions. Buyers recognize that equipment unable to deliver specifications consistently across operational ranges provides theoretical capability, not practical value.

Competition intensified across industries. Margins tightened. Facilities can’t afford equipment that’s operationally temperamental or requires extensive support infrastructure. Technical capabilities need to translate into competitive advantages through improved quality, higher throughput, reduced costs, and operational flexibility.

What Sets It Apart Meaningfully

Setting equipment apart in advanced performance isn’t about impressive specification sheets. It’s proving capabilities under conditions that actually exist in production facilities. Maintaining precision despite environmental variations. Delivering speed without sacrificing accuracy. Providing flexibility without performance penalties.

The ESP platform demonstrates these capabilities through measurable operational results. Specifications maintained across realistic operating ranges. Precision holding through demanding production schedules. Adaptability proven across diverse applications. Reliability confirmed through years of field deployment.

Nothing revolutionary in obvious dramatic ways. Just equipment engineered around operational reality instead of laboratory ideals. Solving problems that matter to facilities facing competitive pressure requiring advanced capabilities without operational complications.

Industries running demanding operations can’t afford equipment that’s technically sophisticated but operationally problematic. The advanced performance needs to deliver value consistently—better quality, higher throughput, improved reliability, reduced complexity.

That’s what genuinely sets this platform apart. Not peak performance under perfect conditions, but sustained excellence across conditions that actually exist. Equipment maintaining advanced capabilities through years of service rather than requiring constant environmental control and careful handling. Investment justified through operational advantages, not just technical bragging rights.