Agriculture has become increasingly technology-driven, where the right equipment directly influences productivity and profitability. Among the essential farm implements used for soil preparation and crop management is the disc ridger. Choosing a dependable Disc Ridger Manufacturer is crucial for farmers who want strong construction, consistent performance, and long-term value. A professional manufacturer designs disc ridgers that improve soil structure, support healthy crops, and reduce manual effort.

Understanding the Importance of Disc Ridgers in Agriculture

Disc ridgers are used to create ridges and furrows in farmland, which play a major role in proper irrigation, soil aeration, and root protection. Crops such as sugarcane, potatoes, cotton, maize, and vegetables benefit greatly from uniform ridge formation. A reputed Disc Ridger Manufacturer ensures that the equipment works efficiently across different soil conditions, including hard, dry, and moisture-rich soils.

By using high-quality disc ridgers, farmers can:

-

Improve water flow and drainage

-

Prevent crop damage caused by waterlogging

-

Enhance soil aeration and fertility

-

Achieve better crop growth and yield

Why the Right Disc Ridger Manufacturer Matters

Not all agricultural implements deliver the same results. A trusted Disc Ridger Manufacturer focuses on quality engineering, durable materials, and real-field testing. Poorly manufactured equipment can lead to uneven ridges, frequent breakdowns, and increased operating costs. That is why selecting an experienced manufacturer is essential for uninterrupted farming operations.

Key benefits of choosing a reliable manufacturer include:

-

Long-lasting and sturdy equipment

-

Reduced maintenance and repair costs

-

Smooth operation with minimal vibration

-

Strong after-sales support and service

Key Features of Disc Ridgers from a Professional Manufacturer

A well-established Disc Ridger Manufacturer incorporates advanced features to ensure performance, durability, and ease of use.

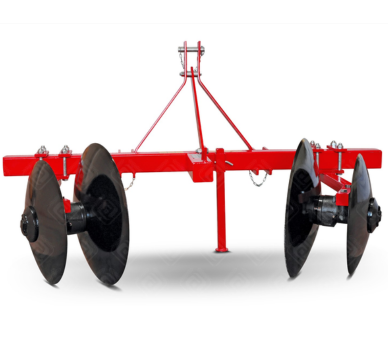

Heavy-Duty Frame Structure

Disc ridgers are built using high-grade steel to withstand continuous field operations. A robust frame ensures stability and strength even in challenging soil conditions.

Precision-Engineered Discs

Proper disc shape, thickness, and alignment are critical for effective ridge formation. Precision-engineered discs allow smooth soil cutting and consistent ridge size.

Adjustable Width and Depth

Modern disc ridgers offer adjustable working width and depth, allowing farmers to customize the implement according to crop type and row spacing.

Tractor Compatibility

A dependable Disc Ridger Manufacturer designs equipment that is compatible with various tractor horsepower ranges, making it suitable for small, medium, and large farms.

Advantages of Buying Directly from a Disc Ridger Manufacturer

Purchasing directly from a Disc Ridger Manufacturer ensures better quality control and cost efficiency. Manufacturers maintain strict standards throughout the production process and can offer tailored solutions for specific agricultural needs.

Advantages include:

-

Competitive pricing without middlemen

-

Guaranteed product authenticity

-

Custom-built disc ridgers for specific crops

-

Faster access to technical support and spare parts

Applications of Disc Ridgers in Farming Operations

Disc ridgers manufactured by a reliable Disc Ridger Manufacturer are widely used for multiple agricultural tasks, including:

-

Ridge and furrow formation

-

Weed control and soil loosening

-

Seedbed preparation

-

Irrigation channel creation

Because of their versatility, disc ridgers are a valuable investment for both traditional and modern farming systems.

Manufacturing Technology and Quality Standards

Leading Disc Ridger Manufacturers invest in advanced manufacturing processes to ensure consistent quality and performance. Modern techniques help improve precision, durability, and overall efficiency.

Common manufacturing advancements include:

-

CNC machining for accurate components

-

High-strength welding for frame stability

-

Corrosion-resistant coatings for longer lifespan

-

Improved bearing systems for smooth rotation

These innovations help farmers reduce fuel consumption and operating costs while improving productivity.

How to Choose the Best Disc Ridger Manufacturer

Selecting the right Disc Ridger Manufacturer requires careful evaluation. Farmers and distributors should consider not only pricing but also quality, service, and long-term reliability.

Key factors to look for:

-

Years of experience in agricultural equipment manufacturing

-

Use of premium-quality raw materials

-

Compliance with agricultural and safety standards

-

Availability of service centers and spare parts

A manufacturer with a strong reputation and customer-focused approach is always a safer choice.

Contribution to Sustainable Farming Practices

A responsible Disc Ridger Manufacturer plays an important role in promoting sustainable agriculture. Efficient disc ridgers reduce soil erosion, improve water management, and minimize fuel usage. Durable equipment also reduces waste by lowering the need for frequent replacements, making farming more environmentally friendly and cost-effective.

Conclusion

Choosing a trusted Disc Ridger Manufacturer is a key step toward achieving efficient, productive, and sustainable farming. High-quality disc ridgers improve soil preparation, ensure uniform ridge formation, and support better crop growth. With durable construction, precision engineering, and farmer-centric designs, a reliable manufacturer delivers long-term value and dependable performance. Investing in the right disc ridger manufacturer ultimately leads to higher yields, reduced operational costs, and long-term agricultural success.