Reliable electrical distribution systems are in high demand due to India’s rapidly expanding infrastructure, industrial growth, and commercial development. At the center of these systems is the distribution board panel, a vital component that ensures organized, efficient, and safe power distribution. Because of this, Distribution Board Panel Manufactures in India play a crucial role in industries such as manufacturing, construction, utilities, data centers, and commercial complexes.

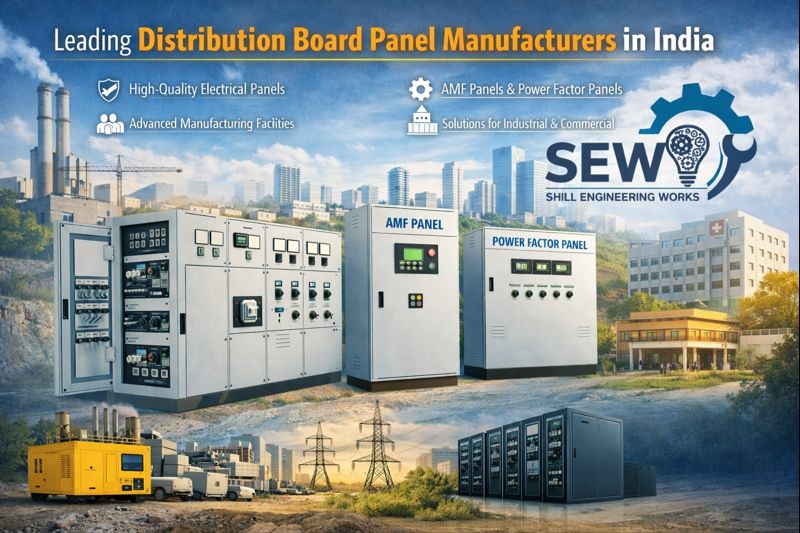

Sew India, one of the top names among Distribution Board Panel Manufactures in India, has emerged as a trusted manufacturer of high-quality electrical panels that comply with both national and international standards. With proven expertise as AMF Panel Manufacturers and Power Factor Improvement Panel Manufacturers, Sew India stands out as a comprehensive electrical panel manufacturing partner.

Understanding Distribution Board Panels

A distribution board panel is an electrical enclosure that distributes power from a main supply to multiple circuits while providing protection through circuit breakers, isolators, and fuses. These panels are essential for:

- Preventing electrical overloads and short circuits

- Enhancing safety for equipment and personnel

- Improving power management and energy efficiency

- Ensuring uninterrupted power distribution

Due to their critical role, industries rely on experienced Distribution Board Panel Manufactures in India to deliver durable, precision-engineered, and standards-compliant solutions.

The Growing Demand for Distribution Board Panel Manufactures in India

The demand for high-quality electrical panels has risen significantly due to:

- Smart city initiatives and large-scale infrastructure projects

- Expansion of industrial plants and manufacturing facilities

- Growth in renewable energy and power distribution networks

- Increased emphasis on electrical safety and regulatory compliance

This rapid growth has positioned India as a global hub for electrical panel production. However, selecting the right Distribution Board Panel Manufactures in India is essential to ensure performance, safety, and long-term reliability.

Sew India – A Trusted Name in Electrical Panel Manufacturing

Recognized as one of the leading Distribution Board Panel Manufactures in India, Sew India is known for its commitment to quality, innovation, and customer satisfaction. With years of industry experience, the company provides customized electrical panel solutions tailored to specific project requirements.

Key Strengths of Sew India

- Advanced manufacturing facilities

- Skilled engineering and design professionals

- Strict quality control and testing procedures

- Compliance with IS, IEC, and international standards

- Timely delivery and dependable after-sales support

These strengths make Sew India a preferred choice among Distribution Board Panel Manufactures in India for industrial, commercial, and infrastructure projects.

Distribution Board Panels by Sew India

Sew India manufactures a wide range of distribution board panels suitable for diverse applications. These panels are designed to manage varying voltage levels and load requirements while ensuring maximum operational safety.

Features of Sew India Distribution Board Panels

- Robust enclosures with superior protection

- High-quality busbars and electrical components

- Modular and compact designs

- Easy installation and low maintenance

- Enhanced protection against electrical faults

As one of the most reliable Distribution Board Panel Manufactures in India, Sew India ensures that every panel delivers efficiency, durability, and a long service life.

Expertise as AMF Panel Manufacturers

In addition to distribution boards, Sew India is also counted among trusted AMF Panel Manufacturers in India. AMF (Automatic Mains Failure) panels are essential for facilities where uninterrupted power supply is critical, such as hospitals, data centers, hotels, and industrial plants.

Importance of AMF Panels

AMF panels automatically detect mains power failure and switch the load to a generator, ensuring seamless power continuity without manual intervention.

Benefits of Sew India AMF Panels

- Automatic changeover between mains supply and DG set

- Reduced downtime and operational disruptions

- Reliable performance during power outages

- Custom-designed solutions for different capacities

The consistent performance and precise engineering of these panels reinforce Sew India’s reputation as one of the leading AMF Panel Manufacturers in the country.

Leadership in Power Factor Improvement Panel Manufacturing

With increasing energy costs and power quality concerns, power factor correction has become a priority for industries. Sew India is also recognized among top Power Factor Improvement Panel Manufacturers, offering advanced solutions to enhance electrical efficiency.

Why Power Factor Improvement Is Essential

A poor power factor leads to higher electricity bills, increased energy losses, and penalties imposed by power utilities. Power factor improvement panels compensate for reactive power and optimize system performance.

Advantages of Sew India Power Factor Improvement Panels

- Reduced electricity costs

- Improved overall system efficiency

- Lower power and energy losses

- Extended lifespan of electrical equipment

As one of the trusted Power Factor Improvement Panel Manufacturers, Sew India helps organizations achieve energy efficiency and compliance with utility regulations.

Applications Across Industries

Sew India’s electrical panels are widely used across various sectors, including:

- Manufacturing and industrial plants

- Commercial buildings and IT parks

- Hospitals and healthcare facilities

- Infrastructure and construction projects

- Power generation and utility sectors

This wide range of applications highlights Sew India’s versatility and technical expertise as one of the top Distribution Board Panel Manufactures in India.

Commitment to Quality and Safety

Quality and safety are paramount in electrical systems. Sew India follows rigorous quality assurance procedures throughout the manufacturing process—from design and component selection to assembly and final testing.

Each panel is thoroughly tested to ensure:

- Electrical safety and insulation integrity

- Load-handling and endurance capability

- Compliance with applicable standards

- Reliable performance under varying operating conditions

This strong commitment to quality ensures long-term reliability and builds customer confidence.

Why Choose Sew India?

Among numerous Distribution Board Panel Manufactures in India, Sew India stands out because of:

- A comprehensive range of electrical panel solutions

- Proven expertise as AMF Panel Manufacturers and Power Factor Improvement Panel Manufacturers

- Customization based on specific project needs

- Competitive pricing without compromising quality

- Strong technical assistance and after-sales support

These advantages make Sew India a dependable partner for both small-scale and large-scale electrical projects.

Conclusion

The importance of electrical panels in ensuring safe and efficient power distribution cannot be overstated. As one of the leading Distribution Board Panel Manufactures in India, Sew India delivers high-performance solutions that meet the evolving demands of modern industries.

With a strong track record as AMF Panel Manufacturers and Power Factor Improvement Panel Manufacturers, Sew India offers complete electrical panel solutions under one roof. Whether for industrial, commercial, or infrastructure applications, Sew India remains a trusted brand committed to quality, innovation, and reliability.