In industries where precision mixing, blending, and processing are critical, agitator seals play an essential role in maintaining product purity, preventing leakage, and ensuring equipment reliability. From chemical reactors to food processing vessels, agitator mechanical seals are designed to withstand high pressures, extreme temperatures, abrasive media, and variable viscosities—making them one of the most vital components in modern industrial mixing operations.

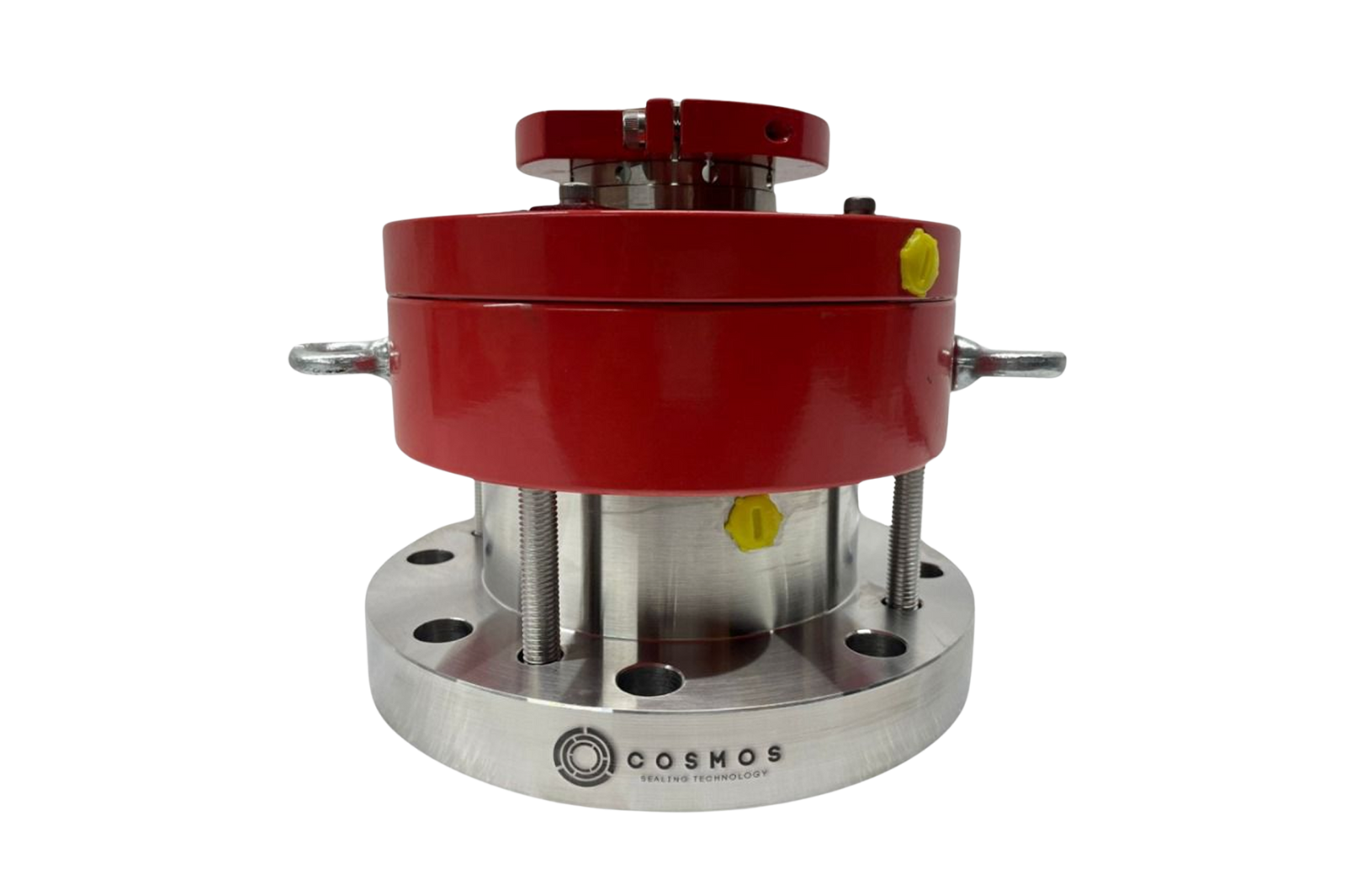

In India, Cosmos Seals India Pvt. Ltd. has emerged as a trusted manufacturer offering some of the best agitator seals engineered for durability, high performance, and long service life. With a focus on innovation and quality, Cosmos Seals provides solutions that meet the needs of chemical, pharmaceutical, food, dairy, petrochemical, and heavy-duty industrial applications.

What Are Agitator Seals and Why Are They Important?

Agitator seals are mechanical seals specifically designed for rotating shafts used in:

-

Mixers

-

Agitators

-

Blenders

-

Reactors

-

Storage tanks

-

High-viscosity mixing vessels

Unlike standard pump seals, agitator seals face more challenging conditions, such as:

-

Slow shaft speeds

-

High radial and axial loads

-

High pressure and vacuum conditions

-

Abrasive and viscous media

-

Large shaft deflections

-

Side load and runout

-

Temperature fluctuations

Choosing the right agitator mechanical seal ensures:

✔ Zero contamination

✔ Leak-proof mixing operations

✔ Higher equipment uptime

✔ Improved product quality

✔ Lower maintenance and operational costs

Why Cosmos Seals Offers the Best Agitator Seals in India

Cosmos Seals is known for designing reliable, high-performance sealing solutions that meet the strict demands of industrial mixing processes. Their agitator seals deliver consistency, durability, and long-term efficiency—even under extreme operating conditions.

Here’s why industries across India trust Cosmos Seals:

1. High-Quality Engineering and Precision Design

Cosmos Seals manufactures agitator mechanical seals using advanced materials such as:

-

Silicon Carbide (SiC)

-

Tungsten Carbide (TC)

-

Resin-impregnated Carbon

-

PTFE, GFT, and advanced polymers

-

Viton, EPDM, and FFKM elastomers

These materials ensure:

✔ Low friction

✔ High corrosion resistance

✔ Excellent thermal stability

✔ Long sealing life even in demanding applications

2. Designed for Tough Mixing Environments

Agitator seals from Cosmos Seals are built to handle:

-

High temperatures

-

Abrasive slurries

-

Chemical solvents

-

High vacuum or pressure differentials

-

Thick, sticky, or viscous media

-

High agitation loads and shaft deflection

This makes them suitable for reactors, fermenters, crystallizers, and processing tanks used across multiple industries.

3. Variety of Agitator Seal Designs

Cosmos Seals offers a comprehensive range of agitator seal solutions:

• Single Agitator Seals

Designed for non-hazardous fluids and general mixing applications.

• Double Agitator Seals

Ideal for toxic, abrasive, or hazardous chemicals, ensuring maximum containment and safety.

• Dry-Running Agitator Seals

Perfect for applications where liquid lubrication is not possible.

• Gas-Lift Agitator Seals

Engineered for ultra-clean processes in pharmaceutical and food sectors.

• Cartridge-Type Agitator Seals

Easy to install, pre-set, and highly reliable.

4. Custom-Engineered Solutions for Industry Needs

Every mixing process is unique. Cosmos Seals offers custom agitator seal solutions designed according to:

-

Pressure rating

-

Temperature limits

-

Shaft size

-

Tank design

-

Media type

-

Speed of rotation

-

Process hygiene requirements

This ensures a perfect match for every industrial application.

5. Industry-Specific Applications

Cosmos Seals agitator seals are widely used in:

-

Chemical and Petrochemical Plants

-

Pharmaceutical & API Manufacturing

-

Food & Beverage Processing

-

Dairy & FMCG Industries

-

Paints, Dyes & Coatings

-

Water Treatment & Effluent Plants

-

Oil & Gas Refineries

-

Cosmetics & Personal Care Products

-

Adhesive, Resin & Polymer Manufacturing

From high-purity applications to heavy-duty mixing, their seals are built for performance.

6. Long-Term Durability and Cost Efficiency

Cosmos agitator seals are engineered to provide:

✔ Longer service life

✔ Lower frictional wear

✔ Fewer breakdowns

✔ Reduced maintenance frequency

✔ Higher equipment reliability

This directly translates to cost savings, reduced downtime, and improved process stability.

Why Indian Industries Trust Cosmos Seals

With strong industry experience, cutting-edge technology, and strict quality standards, Cosmos Seals has become a preferred sealing partner across India. The company offers:

-

High product reliability

-

Fast support and guidance

-

Modern manufacturing infrastructure

-

Quick delivery and easy availability

-

Solutions tailored to Indian industrial environments

Conclusion

Agitator seals are essential for safe, clean, and reliable mixing operations across industries. If you’re looking for the best agitator seals in India, Cosmos Seals delivers unmatched quality, durability, and performance. Their engineered seal solutions ensure maximum containment, optimized efficiency, and long-term dependability for all types of mixing applications.