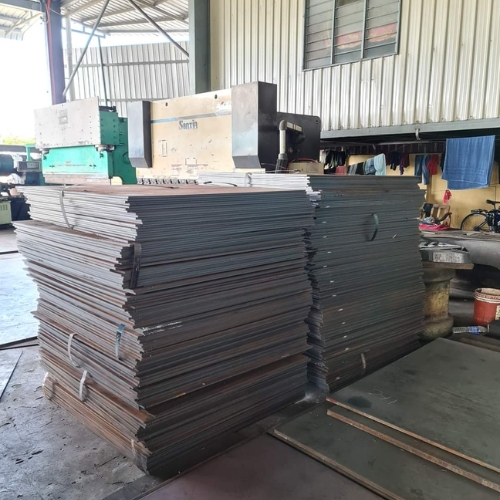

In industries where equipment is exposed to constant abrasion, impact, and heavy loads, selecting the right material is critical. Wear resistant steel plates play a vital role in extending machinery life and improving operational efficiency. A reliable NM 400 plate supplier ensures consistent quality, durability, and timely delivery of plates designed for the most demanding industrial environments.

NM 400 plates are widely used across mining, construction, cement, and material handling industries due to their superior hardness and wear resistance. Partnering with an experienced supplier guarantees that these benefits are fully realized.

What Is NM 400 Wear Resistant Steel Plate?

NM 400 is a high-strength abrasion resistant steel plate with an average hardness of around 400 Brinell (HB). It is engineered to withstand severe wear conditions while maintaining excellent toughness and structural integrity.

Key characteristics of NM 400 plates include:

-

High resistance to abrasion and surface wear

-

Consistent hardness throughout the plate

-

Good impact resistance under heavy loads

-

Controlled chemical composition

-

Suitable weldability with proper techniques

A professional NM 400 plate supplier ensures these properties meet industry standards and customer requirements.

Applications of NM 400 Plates

NM 400 wear resistant steel plates are used in applications where regular steel would fail prematurely due to excessive wear. These plates significantly reduce maintenance costs and equipment downtime.

Common applications include:

-

Mining equipment liners and buckets

-

Dump truck bodies and tipper liners

-

Crushers, screens, and hoppers

-

Cement plant wear parts

-

Earthmoving and construction machinery

-

Conveyor systems and material chutes

Industries rely on a trusted NM 400 plate supplier to deliver plates that perform reliably in such harsh conditions.

Why Choose a Reliable NM 400 Plate Supplier?

The quality of wear resistant steel depends not only on the grade but also on manufacturing standards, testing, and handling. Choosing the right supplier is essential for long-term performance.

Advantages of working with a reputed NM 400 plate supplier include:

-

Consistent hardness and mechanical properties

-

Compliance with national and international standards

-

Material test certificates and traceability

-

Technical guidance for fabrication and application

-

On-time delivery and reliable stock availability

A dependable supplier helps industries minimize risks and optimize productivity.

Manufacturing Quality and Testing Standards

High-quality NM 400 plates are produced using advanced metallurgical processes such as controlled rolling and quenching. Strict testing ensures uniform performance across all plates.

Quality control measures typically include:

-

Chemical composition analysis

-

Brinell hardness testing

-

Impact and toughness testing

-

Ultrasonic testing for internal defects

-

Surface and dimensional inspection

An experienced NM 400 plate supplier ensures every plate passes these quality checks before delivery.

Benefits of NM 400 Wear Resistant Plates

Compared to conventional structural steel, NM 400 plates offer superior performance in abrasive environments.

Key benefits include:

-

Extended service life of equipment

-

Reduced repair and replacement frequency

-

Lower overall maintenance costs

-

Improved productivity and operational efficiency

-

Better resistance to deformation and cracking

These advantages make NM 400 plates a cost-effective solution for heavy-duty industrial use.

Sizes, Thicknesses, and Processing Services

A professional NM 400 plate supplier offers a wide range of sizes and thicknesses to suit various applications. Value-added services further enhance customer convenience.

Common supply options include:

-

Multiple thickness ranges

-

Standard and customized plate dimensions

-

CNC cutting and profiling services

-

Edge preparation for welding

-

Machining as per drawings or specifications

Such services reduce fabrication time and improve accuracy in equipment manufacturing.

Logistics and Timely Delivery

Timely material supply is crucial for project execution and maintenance schedules. A reliable supplier maintains sufficient inventory and efficient logistics systems.

Logistics advantages include:

-

Ready stock availability

-

Safe and secure packaging

-

Fast dispatch and dependable delivery timelines

-

Nationwide and export supply capability

Working with a trusted NM 400 plate supplier ensures uninterrupted industrial operations.

Industries That Depend on NM 400 Plate Suppliers

NM 400 wear resistant steel plates are essential across multiple sectors.

Key industries include:

-

Mining and quarrying

-

Construction and infrastructure

-

Cement and power plants

-

Steel fabrication and heavy engineering

-

Bulk material handling

Each industry benefits from the durability, strength, and performance of NM 400 plates.

How to Select the Best NM 400 Plate Supplier

Choosing the right supplier is crucial for quality assurance and long-term partnership.

Important factors to consider:

-

Supplier experience and industry reputation

-

Availability of test certificates and documentation

-

Range of products and processing capabilities

-

Technical support and after-sales service

-

Competitive pricing and reliable delivery

A well-established supplier adds value beyond just supplying steel plates.

Conclusion

A dependable NM 400 plate supplier plays a vital role in supporting industries that operate in highly abrasive and impact-prone environments. NM 400 wear resistant steel plates provide exceptional durability, reduced maintenance costs, and improved equipment lifespan.

By choosing a supplier committed to quality, testing, and timely delivery, businesses can enhance productivity, minimize downtime, and achieve long-term operational efficiency.