India’s manufacturing sector has witnessed remarkable growth over the past decade, with metal forming technologies playing a vital role in infrastructure, automotive, and construction industries. Among these technologies, roll forming has emerged as one of the most efficient and reliable methods for producing uniform metal profiles. Today, roll forming machine manufacturers in India are catering to both domestic and international markets with advanced, high-performance machinery designed for accuracy, durability, and long-term productivity.

Understanding Roll Forming Machines

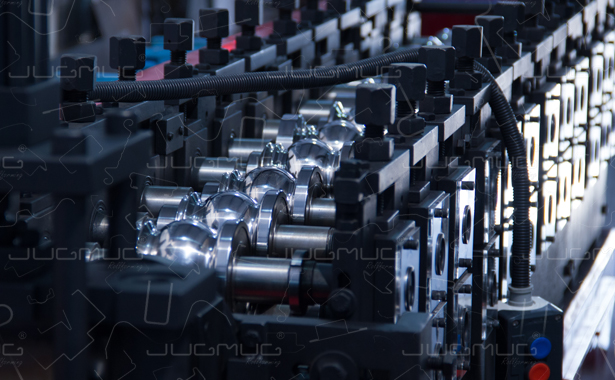

Roll forming is a continuous bending operation in which a long strip of metal, typically steel or aluminium, is passed through a series of rollers to achieve a desired cross-section. The process ensures consistency, minimal material wastage, and excellent surface finish. Roll forming machines are widely used to manufacture roofing sheets, C and Z purlins, channels, guardrails, cable trays, and customised profiles for various industries.

With rising demand for precision-engineered components, the role of reliable roll forming machine manufacturers in India has become increasingly significant.

Growth of Roll Forming Machine Manufacturing in India

India has become a preferred manufacturing hub due to its skilled workforce, strong engineering base, and cost-effective production capabilities. Roll forming machine manufacturers in India have adopted modern technologies, automation, and quality control systems to meet global standards. These manufacturers not only supply standard machines but also offer customised solutions based on specific industrial requirements.

The availability of locally manufactured machines helps Indian industries reduce dependency on imports while maintaining high quality and performance standards.

Key Features Offered by Indian Manufacturers

Leading roll forming machine manufacturers in India focus on delivering machines that combine performance with reliability. Some key features include:

-

Robust machine structure for vibration-free operation

-

Precision-engineered rollers for accurate profiling

-

Smooth material flow for consistent output

-

Energy-efficient drive systems

-

Easy operation and low maintenance requirements

These features ensure uninterrupted production and long service life, making Indian roll forming machines suitable for continuous industrial use.

Applications Across Multiple Industries

Roll forming machines manufactured in India are used across a wide range of industries. The construction sector relies on these machines for roofing sheets, wall panels, and structural sections. The automotive and engineering industries use roll formed components for frames, supports, and reinforcements. Infrastructure projects depend on roll forming machines for guardrails, poles, and safety barriers.

This versatility makes roll forming machine manufacturers in India an integral part of the country’s industrial ecosystem.

Customisation and Technological Advancements

One of the major strengths of Indian manufacturers is their ability to offer customised roll forming solutions. From profile design to machine speed and automation level, manufacturers work closely with clients to deliver machines that meet exact production needs.

Modern roll forming machines are now equipped with PLC control systems, automatic cutting mechanisms, and advanced safety features. Indian manufacturers continue to invest in research and development to stay competitive and meet evolving industry demands.

Quality Standards and After-Sales Support

Quality assurance is a key focus area for reputed roll forming machine manufacturers in India. Machines are manufactured using high-grade raw materials and undergo rigorous testing before dispatch. Compliance with industry standards ensures reliable performance and operational safety.

In addition, Indian manufacturers are known for their strong after-sales support, including installation guidance, operator training, and timely service assistance. This support plays a crucial role in maintaining machine efficiency and customer satisfaction.

Why Choose Roll Forming Machine Manufacturers in India?

Choosing Indian manufacturers offers several advantages, including cost-effective pricing, technical expertise, and flexible manufacturing capabilities. With a growing emphasis on “Make in India,” these manufacturers are continuously improving quality while offering competitive solutions to global clients.

Their ability to deliver durable machines, customised designs, and dependable service makes roll forming machine manufacturers in India a preferred choice for businesses seeking long-term value.

Conclusion

As industries continue to expand and modernise, the demand for precise and efficient metal forming solutions will keep growing. Roll forming machine manufacturers in India are well-positioned to meet this demand with advanced technology, quality engineering, and customer-focused solutions. By delivering reliable machines that enhance productivity and consistency, Indian manufacturers are playing a vital role in shaping the future of the global roll forming industry.