In today’s fast-paced industrial and telecommunications environments, reliable power delivery is not just a convenience, it’s a necessity. Businesses and critical infrastructure projects cannot afford downtime caused by faulty connections, delayed equipment, or inconsistent power distribution. One of the key components ensuring reliable and efficient power connections is the camlock panel. This article explores the importance, design, applications, and benefits of camlock panel solutions in modern power infrastructure.

What is a Camlock Panel?

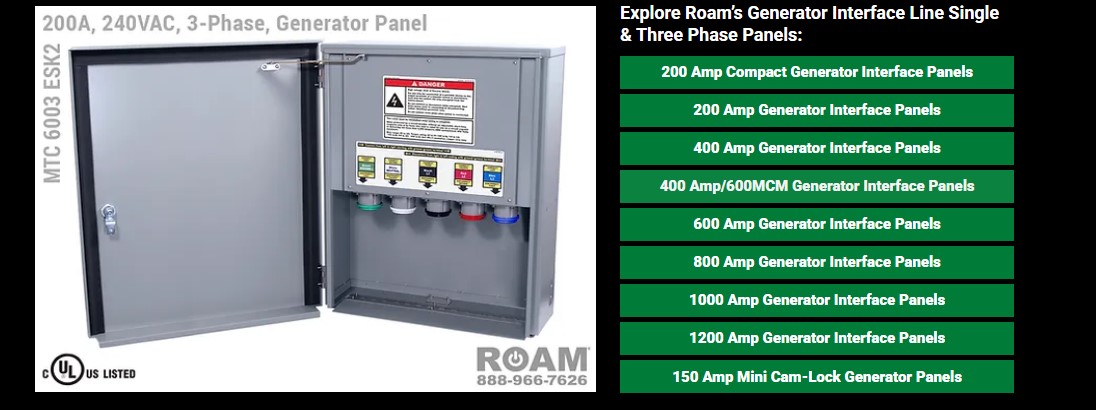

A camlock panel is a type of power distribution unit designed for high-current applications. It uses cam-type connectors to provide secure, fast, and flexible electrical connections. These panels are commonly used in temporary power setups, industrial sites, construction projects, emergency power deployments, and telecom operations.

The camlock design ensures a tight, reliable connection, minimizing the risk of loose contacts, arcing, or accidental disconnections. This feature is particularly important in environments where safety, uptime, and regulatory compliance are critical.

Key Features of Camlock Panels

Modern camlock panels offer several features that make them indispensable for reliable power infrastructure:

-

High-Current Capacity – Camlock panels can handle large currents, making them suitable for generators, distribution systems, and heavy industrial equipment.

-

Durability – Built to withstand harsh environments, these panels are often housed in rugged enclosures that resist weather, dust, and mechanical damage.

-

Ease of Use – The camlock connectors allow for quick, tool-free connections, reducing installation time and human error.

-

Safety Compliance – Panels are designed to meet industry safety standards, including NEC (National Electrical Code) and other U.S. regulatory requirements.

-

Modular Design – Many camlock panels are modular, allowing users to configure connections for multiple devices, generators, or distribution points.

Applications of Camlock Panels

Camlock panels are versatile and find applications across multiple industries:

1. Telecommunications Infrastructure

Telecom sites require uninterrupted power to maintain network connectivity. Camlock panels provide a secure and efficient means to connect backup generators, battery systems, and distribution units, ensuring continuous service even during power outages.

2. Construction Sites

Construction projects often rely on temporary power distribution from generators. Camlock panels allow teams to quickly set up power for lighting, tools, and machinery, reducing downtime and improving site productivity.

3. Utility and Energy Projects

Power generation and utility projects demand reliable distribution for critical operations. Camlock panels enable safe connections between multiple generators and load points, helping maintain grid stability and operational efficiency.

4. Events and Entertainment

Large-scale events require temporary power for lighting, audio, and equipment. Camlock panels simplify setup and teardown, providing fast and dependable connections for short-term but high-demand power usage.

5. Emergency and Backup Power

In emergency situations, fast and reliable power connections are critical. Camlock panels facilitate quick generator integration, ensuring hospitals, data centers, and essential services remain operational.

Advantages of Using U.S.-Manufactured Camlock Panels

While camlock panels can be sourced internationally, opting for U.S.-manufactured solutions offers significant advantages:

-

Faster Delivery – Domestic manufacturing eliminates long shipping delays, allowing projects to meet strict timelines.

-

Enhanced Quality Control – U.S.-based production ensures rigorous testing and adherence to safety standards.

-

Local Support – Technical assistance and after-sales support are easier to access, reducing downtime and troubleshooting complexity.

-

Compliance with Standards – Panels manufactured in the USA comply with NEC and other national codes, ensuring safer deployments.

Selecting the Right Camlock Panel

When choosing a camlock panel, consider the following factors:

-

Current Rating – Ensure the panel can handle the maximum expected load without overheating or degrading.

-

Number of Circuits – Determine the number of inputs and outputs required for your application.

-

Environmental Protection – Select panels rated for outdoor or harsh conditions if necessary.

-

Modularity and Expandability – Panels should be adaptable to future needs without requiring complete replacement.

-

Manufacturer Reputation – Choose products from trusted manufacturers known for consistent quality, reliability, and U.S.-based production if timely delivery is critical.

Future Trends in Camlock Panel Technology

As industrial and telecom infrastructure evolves, camlock panel solutions continue to innovate:

-

Smart Monitoring – Integration of sensors and monitoring systems allows real-time load tracking, predictive maintenance, and remote diagnostics.

-

Lightweight Materials – New materials reduce panel weight without sacrificing durability, simplifying transportation and installation.

-

Eco-Friendly Designs – Panels are increasingly designed to support energy-efficient operations and compliance with sustainability initiatives.

Conclusion

A camlock panel is a vital component in modern power infrastructure, offering secure, reliable, and efficient connections for a wide range of applications. From telecom networks and construction sites to emergency power setups and utility projects, camlock panels ensure consistent performance and safety.

Choosing U.S.-manufactured panels further enhances reliability, quality, and support, making them an ideal choice for critical infrastructure projects across the country. By understanding their features, applications, and advantages, businesses can make informed decisions to maintain uninterrupted power delivery and protect their operations.