Start a tyre recycling business in India with complete guidance on plant setup, machinery cost, required licenses, pollution control approvals, and compliance process. Learn investment details and legal steps to launch a profitable tyre waste recycling plant in India.tyre recycling plant setup, tyre recycling business cost, tyre waste recycling license, recycling plant India, rubber recycling business

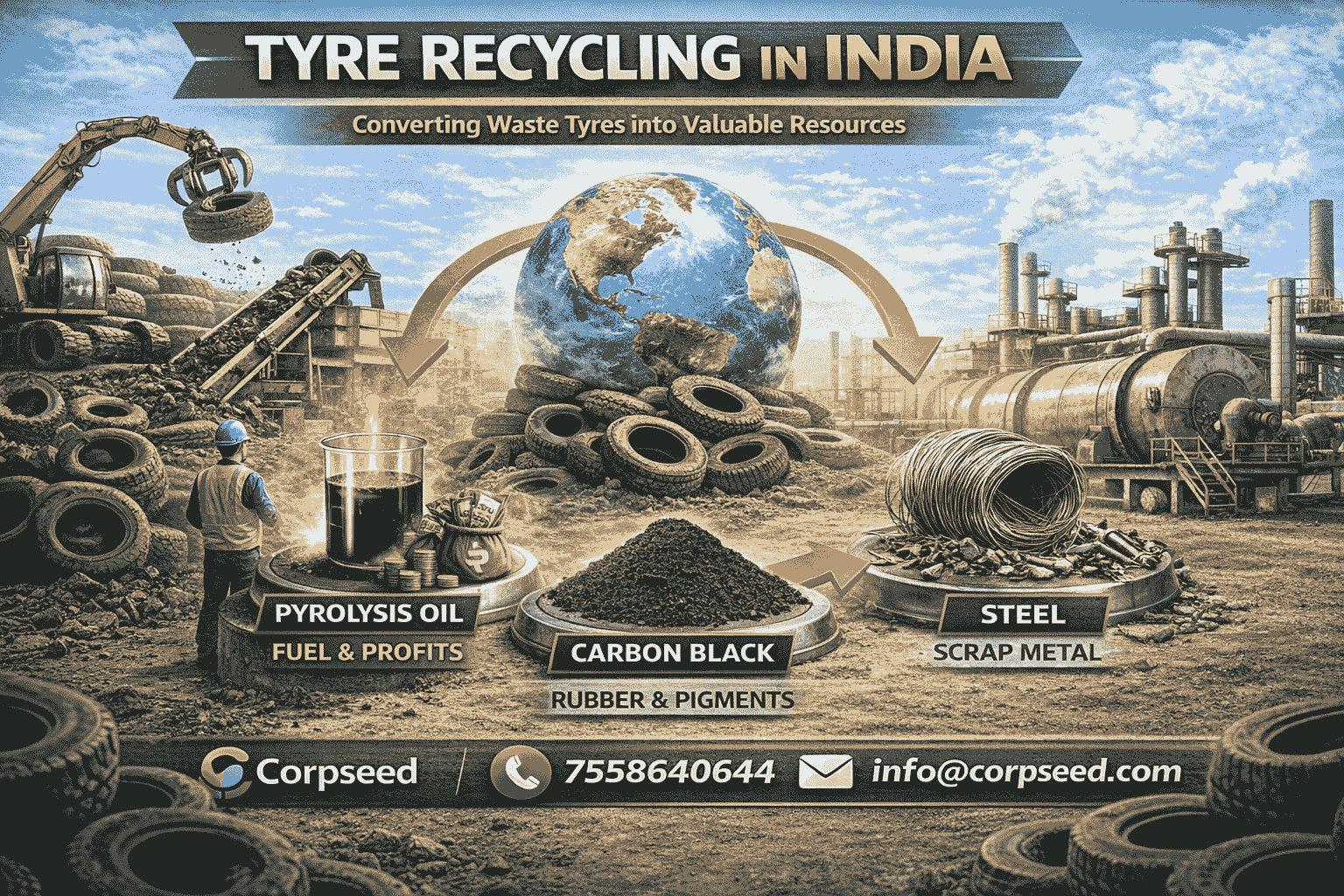

Starting a tyre recycling business in India is a profitable and environmentally responsible venture, driven by the growing volume of end-of-life tyres and strict waste management regulations. Tyre recycling involves processing used and scrap tyres into reusable materials such as rubber granules, crumb rubber, steel, and textile fiber, which are widely used in road construction, playground surfaces, sports tracks, and manufacturing industries.

To set up a tyre recycling plant in India, entrepreneurs must first identify a suitable location and decide the plant capacity based on market demand and investment budget. The overall plant cost depends on machinery, land, utilities, labor, and technology used for shredding, granulation, or pyrolysis. Small-scale units require lower capital, while large automated plants involve higher investment but offer better efficiency and output.

Obtaining the necessary licenses and approvals is a crucial step. Businesses must register with the State Pollution Control Board (SPCB) and comply with the EPR (Extended Producer Responsibility) framework under India’s waste management rules. Consent to Establish (CTE) and Consent to Operate (CTO) are mandatory, along with proper environmental compliance documentation and safety measures.

The tyre recycling process includes collection, sorting, shredding, separation of steel and fiber, and processing rubber into market-ready products. With increasing government focus on circular economy and sustainable waste management, demand for recycled rubber products is rising steadily.

A well-planned tyre recycling business not only contributes to environmental protection but also offers long-term revenue opportunities. With proper planning, regulatory compliance, and market strategy, entrepreneurs can successfully establish a tyre recycling plant in India and benefit from the growing recycling industry.